How It Works: Dropout vs. Carrier-Type Differentials

While every differential housing performs the same basic job—holding the gears that turn engine power into forward motion—there are two key designs you’ll find out there: dropout differentials and carrier differentials. Dropout Differentials Dropout differentials—also called third members—can be identified by their removable front center section. The ring-and-pinion gear set lives inside a carrier assembly that can be easily removed or “dropped out” for service or gear swaps. The legendary Ford 9-inch is the most famous example of a dropout differential, but GM, Toyota, Chrysler, and others have used them as well. The ribbed housing is a quick giveaway that this is a Ford 9-inch. Common Dropout Designs The Ford 9-inch has countless aftermarket configurations, but it’s not alone. Toyota’s lineup includes the 7.5”, 8”, 8” high-pinion, 8” clamshell, 8.5”, T100 IFS, and several 9”, 9.5”, and 10” variations. Mopar fans know dropout-style diffs as banjo-style differentials, with the Chrysler 8.75” being the standout example. Dana has also built many dropout-style units that show up across different makes and models. Fun fact: in some circles, a front-loading dropout differential is called a pig-style diff, and across the pond, the ring gear is known as a crown wheel. No matter what you call it, they all get the job done. Why Choose a Dropout Differential? The main advantage of a dropout differential is ease of gear swaps. Because the entire gear case can be unbolted and removed, all the setup work—ring and pinion installation, backlash adjustment, and pattern checking—can be done comfortably on a workbench instead of under the vehicle. That means faster swaps, easier adjustments, and a cleaner install overall. Carrier Differentials Carrier differentials, on the other hand, are identified by their rear cover. To access the ring and pinion gears or other internals, you remove the cover on the back of the housing. GM’s well-known 10-bolt and 12-bolt designs fall into this category. In British terminology, these are called Salisbury differentials. If you can see the gears from the back, you’re looking at a carrier-style differential. Strengths of Carrier Differentials Carrier-style diffs are extremely common and have a few key strengths. Inspection and troubleshooting are easier—just pop the rear cover and you can see inside. No need to remove the entire center section to diagnose a problem. (Some aftermarket dropout diffs now include rear inspection covers to address this advantage.) One drawback for off-roaders, however, is the exposed diff cover. On rocky trails, a stock stamped-steel cover can get peeled back or punctured by a rock or tree stump—leaving your gears vulnerable. Protect Your Investment with Yukon Hardcore Diff Covers That’s where Yukon Hardcore Performance Diff Covers come in. Built from thick-walled nodular iron, these covers protect lockers, gears, and axles from impacts and housing flex. Each Yukon Hardcore cover features a durable powder coat finish, a magnetic drain plug, a premium gasket, and high-strength fasteners for a clean, reliable install that’s ready for anything the trail can throw at you. Shop Yukon Diff Covers Know Your Setup Understanding the difference between dropout and carrier differentials will help you make smarter choices when upgrading or servicing your drivetrain. Whether you’re re-gearing, installing a locker, or just protecting your investment, knowing how your diff works—and what upgrades it deserves—makes all the difference. Shop Yukon Re-Gear Kits

How It Works: Dropout Vs. Carrier-Type Differentials

A pumpkin is a pumpkin, right? We’re talking about differential housings not jack-o’-lanterns; and hold your horses all are not created equal in the eyes of the drivetrain gods. While diff housings all do the same basic thing: house the gears that make forward motion possible, there are two different designs at work here. Dropout Differentials Dropout differentials, also known as third members, can be readily identified by their removable front center section. The ring and pinion gear set in a dropout diff is contained within a carrier assembly that can be removed or dropped out for easy access. The iconic Ford 9-inch is a dropout or third member type of differential and GM, Toyota, and Chrysler also offer dropout diffs. The ribbed housing is a quick giveaway that this is a Ford 9-inch. Along with the OE Ford 9-inch, there are tons of custom aftermarket Ford 9-inch configurations. The General has dropouts but many of them date back to the 1950s and are not relevant today. Toyota dropout-style diffs consist of the 7.5” rear, 8” rear, 8” high pinion, 8” clamshell, 7.5”, 8.5”, T100 IFS, and numerous 9”, 9.5”, and 10” offerings. In the Mopar world dropout differentials are called banjo-style diffs because someone thought the assembly, when pictured with an axle shaft, had the look of the infamous stringed musical instrument. The Chrysler 8.75” is the automaker’s most popular dropout-style diff. Of course, Dana manufactures a number of dropout style diffs that appear in vehicles across numerous brands. In some circles a front-loading dropout-type diff is known as a pig-style diff. While on the subject of slang, our friends across the pond call the ring gear a “crown wheel” … hey, as long as we’re on the same page it’s all good. Perhaps the main inherent advantage of a dropout diff is easy gear swaps. The gear swap advantage boils down to where you do the work. Since the gear case center section can be unbolted and removed, all the ring and pinion gear installation and tedious setup can be done away from the vehicle on a workbench. It’s more comfortable and access to, and applying leverage on, the key components is much easier. Carrier Differentials Carrier differentials have a cover on the backside of the pumpkin that is unbolted to gain access to the ring and pinion gears and other internal workings of the diff. GM’s 10-bolt and 12-bolt differentials are common examples of carrier-style diffs, which may be referred to as Salisbury differentials by those who speak the Queen’s English. The fact that the gears are visible on the backside of the housing is a telltale sign this is a carrier-type differential. Carrier-type differentials are more popular and they have some strengths when compared to a dropout diff. Troubleshooting is one. Looking for broken or worn parts in a carrier diff is as easy as removing the back cover where in a dropout you have to commit to a full gear case removal to see what’s going on. It should be noted that some custom aftermarket dropout diffs have rear inspection covers to address this concern. There is a less common concern for carrier diff drivers who wheel on the weekends; the diff cover. Traversing craggy terrain can result in the stock diff cover being peeled back like a can of sardines. A protruding rock or tree stump can also spell doom by way of impact damage. The answer: Yukon Hardcore Performance Diff Covers. They look great and are constructed from thick-walled high strength nodular steel to protect lockers, gears, and axles from extreme impacts as well as deflection caused by flex in the housing. Hardcore Performance Diff Covers come with a durable powder coat finish, magnetic drain plug, quality gasket, and high-strength steel fasteners for easy bolt-on installation. Knowing what dropout and carrier-type differentials are and a general idea how they work will help you make more informed installation decisions as you have the knowledge and vocabulary to talk straight with your mechanic. Shop Re-Gear Kits

Dodge, Ford, Jeep Death Wobble Explained

You’ve just picked up a load of landscape gravel. As you make your way home on the highway your Ram 2500 is approaching a railroad crossing on a gently sweeping curve. The planets have just aligned and you are about to experience Death Wobble. The condition of your tires, suspension, and steering have also aligned, producing the perfect blend of sloppiness to induce this dreaded malady. Then it happens. Immediately after encountering the railroad tracks your steering wheel becomes a convulsing nightmare and the stick shift shudders wildly as the entire front of the truck shakes with evil intent. You slow down safely, changing the resonant frequency of the events, and the trembling ceases. Death Wobble is not a good place to be. It not only challenges your control of the vehicle, it damages tires and suspension components. To be fully up-front, Death Wobble can be an issue in any truck with a solid front axle setup. Surf the internet and Jeep Wranglers and Dodge Ram pickups are the leading wobblers, but big Fords feel the effects too. Jeep Wranglers from YJ to JK and Cherokee XJ and beyond are susceptible. On the pickup side, the condition seems to be an inherent issue in first- and second-generation 2500 and 3500 Rams produced from 1994 to 2008 while the Blue Oval crew is mostly concerned about 2005 to 2019 F250s and F350s. Anatomy Of A Solid-Axle Steering System The accompanying diagram will help you better understand where the steering components we will be talking about are located. The schematic is a 1994 to 2008 Dodge Ram pickup setup. Short of the placement of the steering stabilizer and shape of the track bar it is representative of any solid-axle design. What Causes Death Wobble This phenomenon is a convergence of worn components that sparks a chain reaction that leads to Death Wobble. There can be one worn part that causes it or a combination of parts at different stages of wear. With so many contributing factors, nailing down the root cause of Death Wobble can be difficult. Solid axle designs move the front wheels in tandem where in an independent setup the motion is more isolated between the wheels. Something as inane as the aforementioned railroad crossing, an expansion joint of a bridge, even a healthy pot-hole can lead to that first domino falling. Death Wobble often happens when the vehicle is travelling at highway speeds and some manner of steering input being applied. The transfer of motion in solid axle trucks from impacting a road irregularity creates a positive feedback loop that results in Death Wobble. Beyond vehicle control issues, the shaking can damage tires, the sector shaft in steering boxes, tie rods, bushings, wheel bearings, and it often hammers the ball joints. Poorly installed or low-quality lift kits can be a harbinger of Death Wobble. They wreak havoc with steering angles which amplifies the effects of wear on key Death Wobble culprits in the steering system. Big tire upgrades put additional stress on steering system bushings and joints. How you’re using your rig can also change the conditions that lead to Death Wobble. Hauling or towing can also swing the pendulum in favor of Death Wobble because the added cargo load or heaviness of the trailer transfers weight to the rear of the truck, unloading the front suspension. The light front end is more susceptible to the wobble. The Prime Suspects Death Wobble is a tough nut to crack. It can have a singular cause or be the combination of a number of worn parts reaching a critical threshold, even loose bolts in the steering system can cause the phenomenon. Compromises in the following components can set stage. The bottom line here: sloppy steering and suspension tolerances open the door to Death Wobble. Track Bar The track bar is a popular bad actor when it comes to Death Wobble. It’s the universal first part to check for Jeeps, heavy duty Ram and Ford pickups, and any solid axle truck that shows signs of the wobble. We’re taking about the track bar bushing itself as well as the bolt that secures it. The breakdown of the bushing can lead to movement, altered steering angles, and vibration. In Jeeps and Rams, the bolt that attaches the upper track bar (gray arrow) can loosen and, over time, cause the hole in the mount to become oblong which leads to excessive play in the steering. Check the hole for roundness and the bolt for tightness (Jeeps require 125 ft-lbs of torque) and consider replacing the bolt for a higher-grade bolt that can be torqued more. Lifted rigs will have a relocation bracket to keep the geometry in spec. The brackets are another possible point of failure. Improper installation can cause the bracket to become an unwanted pivot point or poor quality will result in a bracket that’s prone to bending… all which will change steering geometry and invite oscillation. On the Ford side, the inner track bar bolt is heavier duty and not prone to bolt movement issues. The outer track bar tie rod ends are suspect. In 2005 to 2016 trucks Ford used a pressed-in joint. 2017-and up trucks have the tie rod end built into the track bar. Deflection is this area ranks high on the cause-and-effect list for big Blue Oval trucks. Tech Tip: To diagnose Death Wobble within the entire steering system have someone crank on the steering wheel, dry steering the system back and forth, and observe (with eyes and ears) the steering linkages and components to identify flex, deflection, and movement. Shop Adjustable Track Bars Ball Joints Ailing ball joints are part of the Death Wobble puzzle. Practically doomed form the start, stock Jeep and Dodge Brothers ball joints have a nylon liner/insert that can compromise their performance. The nylon material is unable to stand up to high mileage not to mention the rigors of off-roading. In Dodge trucks the passenger side ball joints tend to show more wear. Tech Tip: The answer here is upgrading your Ram or Wrangler to heavy-duty Yukon ball joints. These ball joints are more rigid and built with superior materials to handle whatever you throw at them. Ball joints are not as big a wear item on Fords because their design is better. They can come into play when addressing alignment as the joint rides in the caster shims. A Ford service bulletin calls for an increase in camber and these shims are a popular topic in forums. It’s difficult to diagnose shims as the problem but adding a little caster is known to help on newer Ford trucks that are experiencing Death Wobble. Tech Tip: To evaluate ball joint wear jack up the front of the vehicle and leverage the tire with a pry bar. Pry the tire in an up-and-down motion. If the tire moves beyond expected sidewall deflection and/or if you hear/feel and mild clunk, your ball joints are likely toast. It should be noted that alignment is an overarching concern when it comes to Death Wobble. It sets a false foundation and magnifies the shortcomings of other components in the steering/suspension systems. It may be wise to check alignment as part of your Death Wobble troubleshooting regime. Shop Ball Joints Steering Linkage/Tie Rod Ends Ram owners need to know their linkage. The type of track bar/steering linkage you have will impact your rig’s tendency to wobble. As always, the situation can be compounded by the use of larger tires and suspension lifts that put more stress on the steering system. There are two linkage types: Y-Style and T-Style. In a Y-Style, fitted on second- and third-gen Ram pickups, circa 1994 to 2008, the outer tie rod bolt is parallel to the ground and the steering bar bolts to the pitman arm. The problem with this setup is how toe changes as the suspension articulates, putting additional stress on bushings and accelerating tire wear. Tech Tip: The passenger side tie rod end is a known offender. Evidence of its guilt can be seen in more tire wear on the front passenger-side tire. Note: Fords can also suffer from worn tie rod ends. T-style steering debuted in fourth-gen Ram pickups, 2009 to 2018. In this design the outer tie rod bolt is perpendicular to the ground and the pitman arm and steering bar attach via a clip (not bolted to the bar). Tech Tip: Swapping to this newer design is a great way to upgrade the system and take one Dodge/Jeep Death Wobble cause off the table. The steering linkage, namely the steering stabilizer, has been touted as a leading cause of Death Wobble for Ford Super Duty owners. In fact, a service bulletin was issued for 2017 to 2019 F250 and F350s. While the stock stabilizer is cheap and not up to the task, replacement is often a temporary fix that masks the true cause of the wobble by better absorbing that first wave of vibration. Consequently, the condition often returns after a few months. Shop Tie Rod ends Steering Box There are many different lines of thought when it comes to the cause-and-effect of Death Wobble. One of the more interesting theories on the Dodge side centers on the steering box and the role hydraulic pressure of the power steering plays in the Death Wobble drama. The worm gear in the box is hydraulically actuated via an inner spool valve and outer spool valve. When you work the steering wheel, these valves interact which opens the grooves between them. Hydraulic pressure enters via the grooves and the steering box turns the wheels by way of the torsion bar. When the vehicle encounters train tracks, pot holes, expansion joints, or whatever the system’s loose tolerances allow the spool valve to release but there is still pressure trying to open the valve and steer the vehicle… setting off a repeating loop where the hydraulics bounce between turning one way and the other which makes the steering wheel shake from side to side. As mentioned earlier, Ram owners can swap to a fourth generation (2009-2018) steering system or an aftermarket steering box setup from Redhead, Moog, or Mopar to help alleviate this problem. Tires & Shocks We’re ending this dubious list with tires and shocks because they can be both a cause and effect of Death Wobble. Tire wear characteristics and sidewall stiffness are at issue here. Irregular wear in the form of cupping on the tread blocks factor most prominently. A lack of sidewall stiffness is only a factor if it adds to the sloppiness of the suspension/steering as a whole. Cupping is a distinct low spot in the middle of a tread block. In some cases, uneven wear at the edges of the tread block can also be problematic. Pronounced, uneven tire wear plays into a ramping effect that can progress into Death Wobble. Tech Tip: One way to diagnose the impact of your tires is to swap suspect front tires to the rear of the vehicle or install new/different tires and go for a test drive. Beyond that, pay close attention to tire pressure (front from side to side), check tire balance periodically, and consider rotating tires on an accelerated schedule. Blown shocks can impact tire wear, suspension performance, and steering and should also be monitored. Shop Shocks Shop Suspension Lift Systems Wobble-Spotting This isn’t folklore. The NHTSA has issued a number of recalls addressing the matter on 2003 to 2008 Ram pickups. They include a recall of 700,000 vehicles for defective left tie rod assemblies, 242,780 vehicles for outer tie rod ball studs, and one for 1,500 trucks that have aftermarket pitman arms installed. There have also been class action lawsuits filed by vehicle owners regarding Death Wobble in 2018 to 2020 Wranglers and Gladiators and 2005 to 2019 Ford F250 and F350 Super Duty pickups. While it may seem that Death Wobble happens all of a sudden there are some clues to be mindful of. The problem is the subtlety of the progression means the tight, on-center feel that inspires confidence fades slowly. It will start with steering slop, dead spots in the steering where you get a numb feeling from the wheel. This can progress to bump steer and then it’s game-on. Once Death Wobble starts it will become more intense and easier to induce. Death Wobble is a tricky customer. It is the result of many worn parts creating the proper conditions. Part of the deception is how fixing one thing will make Death Wobble stop but what has actually happened is the threshold of where Death Wobble is initiated has been moved back. When one of the other component systems i.e. tires, shocks, ball joints, steering boxes, or track bar bushings wear further the threshold will be reached again and the shaking will return. The best practice solution is to use high-quality lift kits, install them properly, and keep a keen eye on the wear properties of all the systems listed here and maintain them religiously or replace them before the harrowing experience that is Death Wobble visits you.

Jeep Wrangler Guía de observación de la transmisión

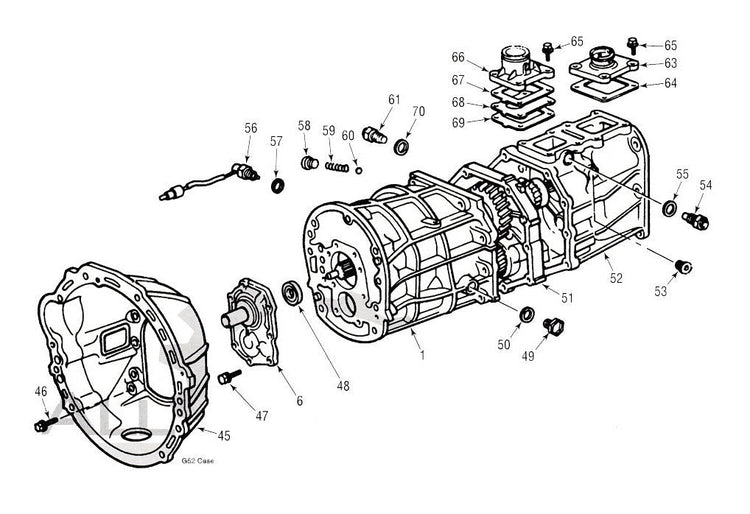

AX-15 – Manual de 5 velocidades Jeep Wrangler: 1988.5 - 1999 con 6 cilindros en línea, 4.0 litros Hechos: Se reemplazó una caja de cambios débil Peugeot BA10 Relacionado con la Toyota Supra Turbo R154 manual La mejor transmisión de 5 velocidades instalada en un Wrangler Consejos: Carcasa intermedia completamente de aluminio Solo se instala en un motor de seis cilindros. Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 16 1/2” Estrías Saliente: 7 1/8” Relaciones de transmisión: 1 1ª primera 3.83, 2ª segunda 2.33, 3ª tercera 1.44, 4ª cuarta 1.00, 5ª Quinta 0.79 AX-5 – Manual de 5 velocidades Jeep Wrangler: 1984 - 2006 XJ, YJ, TJ con 4 cilindros en línea de 2.5 litros Hechos: Quinta marcha propensa a fallas, sincronizadores deficientes, fugas en los rodamientos (anteriores a '94) Las variantes AX-5 incluyen Toyota G52, W58 y R151 Consejos: Carcasa intermedia completamente de aluminio, placa intermedia de hierro fundido Parece AX-15, así que ten cuidado. Solo se instala en un motor de cuatro cilindros. Eje de entrada de 14 estrías Eje de salida de 21 estrías Largo: 15 5/8” Estría Saliente: 7 1/2” Relaciones de transmisión: 1ª primera 3.92, 2ª segunda 2.33, 3ª tercera 1.44, 4ª cuarta 1.00, 5ª Quinta 0.85 NV3550: manual de 5 velocidades Jeep Wrangler: Wrangler 2000 - 2004 con 6 cilindros en línea de 4.0 litros Hechos: AX-15 reemplazado Compatible con la versión de 23 estrías de la caja de transferencia NP231 Consejos Carcasa de aluminio Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 16 3/4” Relaciones de transmisión: 1ª primera 4.01, 2ª segunda 2.32, 3ª tercera 1.40, 4ª cuarta 1.00, 5ª quinta 0.78 NSG370 – Manual de 6 velocidades Jeep Wrangler: Wrangler de 2005 en adelante, Wrangler Rubicon de 2004 en adelante Hechos: NV3550 reemplazado Compatible con 4.0 litros I6 y 3.8 litros V6 Consejos: Caja completamente de aluminio Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 23 1/2” con 6 campanas de acoplamiento en línea Largo: 24 3/4” con campana de acoplamiento V6 de 3.7 L Relaciones de transmisión: 1ª primera 4.46, 2ª segunda 2.61. 3ª tercera 1.72, 4ª cuarta 1.25, 5ª quinta 1.00, 6ª sexta 0.84

Driveline Angles & Vibration

I have had more than a few customers come back to our service shop after a gear ratio change to complain that we caused a new vibration in their vehicle. In actuality, we inadvertently caused the vibration by increasing the driveline speed. When changing to a lower gear ratio (numerically higher) the driveline speed increases proportionally to the change in the ratio. For example, when changing the ratio from 3.08 to 4.56 there is a 48% change in the ratio and a 48% increase in driveline speed. This means that a vibration that would have been noticeable at about 90 mph is now noticeable at 60 mph. This higher driveline speed makes the vibration more noticeable because while it previously existed at 90 mph, it may have gone unnoticed due to the amount of vehicle vibrations it had to overcome in order to be noticed. If the customer installed taller tires and raised the vehicle before changing the gear ratio, the vibration is probably caused by the lift. This vibration caused by the lift and wrong driveline angles would not be noticeable until the new ratio was installed, since the tall tires and stock ratio kept the driveline speeds too slow for the vibrations to be felt. Vibrations due to wrong angles are usually easy to identify because they are harmonic or cyclic. This means that the vibration varies in pitch or intensity even when traveling at a steady speed. The results is a “whir … whir … whir” type of noise. The solution to wrong angles is easy in theory, but not always easy in practice. There have been many good technical papers written on this subject, so I won’t go into detail now. I will however cover a few of the basics. In order for a two U-joint driveline to be free of vibration it must be in balance, and the angle of the front U-joint must be the same as, or very close to, the angle of the rear U-joint. If there is a noticeable difference in the angles, there will be a vibration. If it is not possible to match the front and rear angles, a constant-velocity joint can be used at the transfer case end with no angle in the U-joint on the differential end. Although it is expensive, and only works if the pinion is not offset side-to-side from the output shaft, this is the only cure in many lift situations. I have seen vehicles use a constant-velocity joint at each end of the driveline. This is more expensive but will fix any angle problem. Another solution is to rotate the differential pinion angle up or down to match the front angle. This is usually not easy and can be accomplished with wedges, by moving the spring pads, or by rotating the axles tubes in relation to the differential center section. For some vehicles there are aftermarket kits available for lowering the transfer case or installing adjustable length control arms. Although these may seem like extreme measures, they are sometimes the only way to eliminate or lessen vibrations. Note: If the vehicle has a differential pinion offset to the side from the center of the output shaft on the transmission or transfer case, the angles due to this offset will not cause vibration. This is because the pinion shaft and the output shaft are still parallel with respect to these side-to-side angles. I have seen some lifted vehicles that vibrate no matter how much care is taken to balance the driveline and match the angles. It is one of the things that we sometimes have to live with in order to have a lifted vehicle. Popular Resources: Diagnosing Noise (Part 1) Ford 9 Inch Differential Information Four Critical Ring & Pinion Settings