Diagnosing Noise (Part 1)

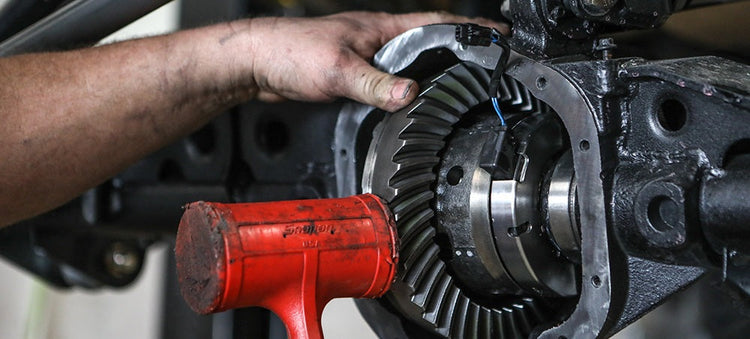

Many things can go wrong inside a differential. Although the hints are often subtle, most impending failures give fair warning in the form of noise. Several situations can create ring-and-pinion noise. If the gears have been quiet and begin to howl, they are probably worn or wearing. If the gears howl during deceleration only, it’s possible that the pinion-bearing preload has loosened. Howling under acceleration at all speeds indicates that something in the differential — gears, pinion or carrier bearings — has worn or no longer keeps the gear alignment correct. If the gears howl while accelerating over a certain speed range, but not all speeds, it’s likely that the gears are worn due to lubrication failure or overloading. When a newly installed gear set howls, suspect the design or setup. A common problem is worn carrier bearings, as indicated by a low-pitch rumble above 20 mph. On vehicles with C-clip axles, the noise may vary while negotiating turns. Worn pinion bearings can cause whirring noises at all speeds, under deceleration and/or acceleration. Pinion bearings tend to whir, rather than rumble, because the pinion is turning several times faster (depending on gear ratio) than the carrier. Badly worn bearings can also cause howl if they do not support the gears correctly. Worn wheel bearings can be difficult to determine. A very bad wheel bearing typically makes itself heard with great clarity; it’s the bearing that is going bad, but not destroyed, that is hard to find. Turning back and forth from hard right to hard left can identify the culprit; however, I’ve been fooled by right-front wheel bearings that make noise when turning right (which heavily loads the inside-left-front wheel bearing, but also loads the outside-right-front bearing). One common situation that may not make any noise: The pinion spins, but the tires don’t rotate. Broken spider gears can render the differential immobile, and usually make a loud, crunching sound as they make their final departure. A broken ring gear will allow the differential to propel the vehicle for about eight feet at a time, then bang or grind as the section with broken teeth tries to engage the pinion. Depending on ratio, a broken pinion tooth (or teeth) will clunk about every two or three feet. A broken axle is easily determined. After it breaks, a C-clip design axle can be pulled out of the housing without unbolting anything — or may even find its own way out. On many bolt-in-design axles, the wheel will give the broken axle shaft away by cambering in at an angle. A high spot on a gear tooth may sound similar to a broken gear, but will only make noise while accelerating or decelerating, since the spot appears on just one side of the offending tooth. A high spot on the ring gear will make a heavy clicking sound about every eight feet; a high spot on the pinion makes noise every two or three feet and is much more pronounced due to its higher frequency. Whether large or small, differential noise is telling you something. Listen carefully! If in doubt, pull off the cover or remove the third member for a closer look. Catching a bad part before is ruins others is definitely worth the effort. Popular Resources: New Gear Break-In Properly Setting Preload with Side Adjusters Size Matters

Thick Gears and C-Clips Can Coexist

With a little time and a common bench grinder, you can modify your existing cross shaft to work with a thick ring gear. Be careful to cool the metal often so that it does not become soft. A cross-pin with a notch in the center can be rotated so that the notch allows the axle to be pushed toward the center of the differential. This allows just enough axle movement to install the c-clips one at a time. With the use of low gears for more power often comes the need for a ring gear that is so thick that the spider gear cross shaft interferes with the ring gear teeth. I often get calls from people who are unsure of how much they can grind off of the cross pin shaft or ring gear teeth and still have a strong rearend. There are many rearends that use c-clips to retain the axle shafts. The c-clip is kept in place by the retaining groove in the side gear. As long as the clip is kept within the confines of the side gear, it cannot slip off the end of the axle. When fully assembled, the axle can not move out because the c-clip stops against the side gear. The axle can not move towards the center of the differential because the end of the axle touches against the cross-pin shaft. As long as the cross-pin shaft is in place, the axle is retained and can not be moved inward or outward, and the c-clip cannot be removed. In order to remove or install the c-clips, the spider gear cross-pin shaft must be removed or positioned so the axle shafts can be pushed toward the center of the differential. Then the c-clip can be slipped off the end of the axle. After the c-clip is removed, the axle shaft can be pulled out of the rearend housing. This is only necessary when the rearend uses c-clips to retain the axle shafts. Any rearend that does not use c-clips will not have problems with thick ring gears. There are four ways to deal with the combination of a thick ring gear and c-clips. My least favorite solution is the use of a c-clip eliminator kit. This method uses pressed-on ball bearing type wheel bearings that replace the flat roller bearings and c-clips. One problem with c-clip eliminators is the need to modify the rearend housing end to accommodate the different bearing design. This modification is NOT reversible and should be well thought out before implementing. Also, the replacement ball bearing wheel bearings do NOT last very long and can typically wear out in as little as eight or ten thousand miles.Another method involves modifying the stock cross-pin shaft, or purchasing a modified one. There are two ways to modify the cross-pin shaft and both work well in most cases. The first one works in virtually every case and has been around for a long time. It involves grinding a relief in the middle of the shaft. The relief needs to be as long as the width of the end of the axle, and as deep as the thickness of the c-clip. This grinding does not severely weaken the cross pin shaft. Most notched aftermarket shafts are made of special high-strength metal and are heat-treated to make them stronger than the stock parts they replace. The second grinding method is used by Ford, and will work in many cases where the ring gear is not so thick that it interferes more than about an eighth of an inch (0.125″). This method involves grinding a flat from the center of the shaft (lengthwise) to one end of the shaft. This flat allows the shaft to be pulled halfway out over the ring gear teeth, and exposes the end of the axle shaft to freedom so it can be moved towards the center for the differential for c-clip removal. Even though the flat removes half of the axle contact area from one side of the cross-pin shaft, the remaining half is plenty to carry the end load of the axle. In some cases the ring gear is too thick for the Ford flat-sided cross-pin shaft to clear the ring gear. In this situation, I grind the pin a little further, or I grind off the toe end of the ring gear teeth that are in the way just enough to clear the shaft. In many cases I have removed up to 3/16″ (about 0.200″) from the toe end of the ring gear teeth with no effect on strength. The last method is actually is the easiest and works in a great many situations. By grinding off only the toe portion of the ring gear teeth that interfere with the cross-pin shaft, you can make the thick gears work without the need for a special cross shaft. Although removing up to about 3/16″ does not hurt the gear strength, I do not recommend removing more than 3/16″ and I am very careful to grind parallel to the axis of the shaft. I remove only enough of the teeth to allow the shaft to clear. The gear teeth can be ground with an ordinary bench grinder if the gear is removed from the carrier, or a high speed 3″ cut-off wheel works very well. Just remember to grind carefully and do not let the metal get too hot. Popular Resources: Diagnosing Noise (Part 1) Ford 9 Inch Differential Information Four Critical Ring & Pinion Settings

Do I Really Need To Buy Another Carrier?

When changing the gear ratio for more power or more speed, sometimes a new ratio requires a different height carrier case. Carrier height changes are commonly referred to as a “carrier break”, although this doesn’t have anything to do with broken parts. What it does refer to is the difference in the ring gear mounting height on the carrier case itself or a breaking point from one height to another. When the gear ratio is changed, it is accomplished by changing the number of the ring gear teeth and / or the pinion gear teeth. The gear ratio is determined by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. For example, 41 divided by 10, which equals 4.10 for a gear set with 41 ring gear teeth and 10 pinion teeth. As the ratio increases numerically, the ring gear usually stays the same diameter which requires that the pinion gear diameter gets smaller. The smaller pinion gear will not reach the ring gear unless the ring gear is made thicker or the carrier case mounting flange is moved closer to the smaller pinion gear. The ring gear material is very expensive and it is far cheaper (especially when building millions of rear ends for production) to change the position of the carrier flange. Changing the flange height usually requires very little or no extra material on the carrier case. An example of a popular rear end that has a carrier break is the Dana Spicer model 44. The D44 uses two different height carriers. When using ratios that are 3.73 or numerically lower (such as 3.54 or 3.07) a short carrier case is used to allow the large pinion gear to fit in the housing and move the carrier flange far enough away for the ring gear to have thickness left to support teeth. When using ratios that are 3.92 or numerically higher (4.09 all the way to 5.89), a taller carrier case is used to move the ring gear closer to the small pinion, without having to use an excess of expensive ring gear material. In order to avoid the expense of a new carrier case, some people use ring gear spacers. A spacer is a quick fix, but from my experience, not a good idea. If the spacer pushes the ring gear up off of the pilot surface that centers it on the carrier, it will have to rely on the ring gear bolts to hold it centered. The ring gear bolts are neither strong enough or accurate enough to center the ring gear correctly. This in turn causes the ring gear to “walk” around on the carrier and the tooth contact will suffer. Before you know it, the gear set will be noisy, wear out, orbreak. I have seen a very few cases where the ring gear pilot surface on the carrier is large enough that it could still touch the ring gear when using a spacer. This is somewhat better than no contact, but the bolts will still be overloaded and the unit will not last. If your ratio change calls for a different height carrier case,there are a few options that will work just fine. Thick ring gear ring & pinion sets are available for many popular applications. The thicker gears have absolutely no side effects. The thicker ring gear has lots of material exposed to the oil so it runs just as cool as a thin gear set. Not only has the aftermarket used thick ring gear sets for many years, many original equipment vehicles have used thick ring gear sets or offered thick gear set options. For example, Ford does not use any carrier breaks on any of their corporate rear ends which means that many of their gear sets could be considered “thick”. The other option that will solve the problem of dealing with a carrier break is the obvious. Buy a new carrier. This may sound expensive and in some cases it is. In many cases the carrier case is less than $100. Or, it may be a good time to upgrade to a positraction or locker. Replacing the carrier with a posi or locker allows you to upgrade and get the appropriate carrier at the same time. Next month will include a list of carrier brakes for popular truck, passenger car, and Jeep rear ends.

Differential Cost: When Is Too Much Really Too Much?

We get a lot of questions asking how much it should cost to have a rearend setup. Unfortunately, the answer is never simple, due to all the variables involved. The hourly rate a shop charges can vary from as little as $60 to over $200 per hour. Labor charges may depend on location, competence, warranty, overhead, and the individual shop or mechanic’s desire to work on differentials. Access to a flat rate book that provides standard hours required to do the job can be helpful. Ultimately, the shop is going to charge whatever they feel is fair, and we have found the flat rate books to be misleading at times. The guidelines we are about to present are only provided to help the reader in their search for a fair deal and should not be taken as gospel. If someone wants to charge more, and you want to have them do the work, then the only solution is to pay the price. However, if you feel that an equally good job can be done elsewhere, then so be it. Always consider the cost to be secondary to the quality of the work you receive. The following rates are per axle for most passenger cars, Jeeps, mini trucks, and half ton trucks, if the vehicle is driven to the shop: Rebuild with new bearings and seals using same ring & pinion: 4 to 6 hrs. Install ring & pinion, and bearings and seals if needed: 5 to 7 hrs. Install limited slip or locker, without removing pinion: 3 to 4 hrs. This list of variations or exceptions to the above rule are a few of the common things that make the job more difficult, or easier, and require an adjustment to the cost: Differential is brought in out of the vehicle: Subtract 1.5 hrs. Three quarter and one ton trucks: Add 1 hrs. General Motors independent front suspension: Add 3 to 4 hrs. Late model independent front suspension (excl GM): Add 1 to 4 hrs. Two-piece tapered axles: Add 1.5 hrs. Motorhomes or large Box Vans that do not fit on common lift: Add 4 to 8 hrs. Another thing to be aware of when shopping around is warranty. Any shop that is familiar with differentials will probably have some limitations to their warranty. Some of the common warranty restrictions that we use in our shop are: mini and mid-size trucks (Jeeps, Ford Rangers with 7.5″ diff, Toyota trucks) with tires taller than 31″; half ton trucks with tires taller than 33″; three quarter and one ton trucks with tires taller than 35″; trucks used for towing have a shorter than standard warranty; and vehicles used for competition or racing are not warranted. These may seem like extreme limitations, but they are sometimes necessary to protect the shop from people who abuse their vehicles on or off road. If you purchase parts directly from the shop doing the work, expect to pay a little more. Every shop has the right to make a profit when stocking or handling parts. And shops can be very helpful if there’s ever any warranty issues related to the parts. Use your best judgment and remember that supply and demand always hold true when it comes to quality parts and service. Popular Resources: New Gear Break-In Properly Setting Preload with Side Adjusters Size Matters

Choosing A Differential Repair Shop

So you don’t have the time to work on your own differential? Who can you trust to do a good job? Whenever I take my truck to someone for repairs, I always cross my fingers, even if I know them. The automotive repair industry has a bad reputation for a reason, mostly because there are many unqualified or corrupt people in the industry. Now don’t send me a bunch of letters defending the trade. I have made my living by doing repairs and selling parts for more than twenty years now, and I know that there are a lot of good people involved in auto and truck repair. However, identifying them can be difficult.Finding a good diff repair shop can be harder than just finding someone who is honest and who truly cares about doing the job right. They must also be competent. When it comes to differentials, most mechanics, dealerships included, do not like to work on them. There are not many good manuals available, there are no really good training programs that I am aware of, and I have found differentials to be more of an art than a science. Unfortunately, this also leaves repair shops feeling frustrated in their search for a good diff mechanic. When it comes to differential repair, I recommend trying to find someone at, or through, a four wheel drive shop. Four wheelers typically have more experience with diffs than speed shops or machine shops, although there are exceptions. Even if they do not do the work themselves, they can probably recommend someone who does. Before having any work done, I always like to see the mechanic’s work area. If the shop is clean, organized, and the personnel are proud to show it off, then I am somewhat more at ease. I also like to ask a lot of questions before I turn over my keys. Where do they get their parts from? Do they have them in stock? What kind of warranty comes with the parts and labor? How long will it take to do the job? How many diffs do they do each week? One thing I always do is insist on getting an estimate for tear-down, inspection, and reassemble, in case I decide not to have the repairs done after receiving the estimate. Also, I always insist on an exact estimate for the repairs needed prior to them starting any actual repair work. Some states have excellent laws that protect the customer by requiring all repair facilities to provide these estimates, while some states provide no protection for the consumer at all. Finally, I recommend paying with a credit card. This not only insures that you have some recourse in the event of a problem with the shop, it also weeds out the shops that credit card companies will not do business with. One other thing I want to mention is that although I do not like to drive long distances just to have my truck worked on, I have found that the drive to a reputable shop is usually easier than the hassle of a bad repair experience. Do I sound more than a little paranoid? Over the years, there have been many times that I have chosen not to work on my own trucks for one reason or another, and it has always made me uneasy to leave them with someone new. Fortunately, there are a lot of honest, competent repair facilities out there. Be aware though, they want your money as much as you do, and it never hurts to be cautious and ask a lot of questions. Simply taking time to investigate potential repair shops before any work is done will lower your chances of receiving a poor repair and increase your chances of receiving a fair deal. Popular Resources: New Gear Break-In Properly Setting Preload with Side Adjusters Size Matters