Yukon at the 2021 King of the Hammers

For 10 years Yukon Gear & Axle has been a part of the toughest one-day race on the planet, King of the Hammers. It began as a group of friends, all heavy off-road builders, that met in the dry desert outside of Joshua Tree, California, just 50 miles east of Los Angeles. In those days it was about climbing the toughest trails over boulders the size of a Volkswagen Bug, and the loser bought the beer. From there the party grew. King of the Hammers is now a city of people from all walks of life. They come in motorhomes, campers, towing motorcycles, quads, side-by-sides, Jeeps, Toyotas, Samurais and even lifted limousines. Making the trek to Johnson Valley is awe-inspiring, it’s The Burning Man of off-road racing. Last year, more than 60,000 people came from all over the world. Some to watch, some to race. On the lakebed, more than 400 teams participated. It was an attendance record for King of the Hammers. This year with COVID issues and California leading the nation in cases, the race went on with heavy mitigation rules. The event didn’t disappoint. The overall crowd was down but only to an estimated 40,000 spectators and again more than 400 race teams participated. King of the Hammers is a full day race, encompassing more than 300 miles through the desert and on trails. Drivers are in their cars by 6 a.m., lining up and waiting for their turn for the green flag. Racing begins at 8 a.m. The fastest cars can finish in five to seven hours with many working all 12 hours before timing out just to finish. For most, there is no podium, just the personal satisfaction of finishing the race. Making the full distance is quite an accomplishment. In Friday’s event, 123 cars started but only 35 finished. Team Yukon is comprised of 12 race teams all in different classes. These are the guys we put our money on to hit a top finish. Beyond that, you can’t turn your head around in the pits and not find a Yukon decal on a car. On the track, teams of race cars begin each race and qualifying run, goosing the throttle over the Yukon Launch, a jump mere yards off the starting line. Yukon is the official sponsor of the 4500 Modified Class and each year owns the real estate in the front row of all racing pits. Each pit flies U.S.A. and Yukon flags to drape the desert with respect. In the Yukon pit, we show up with parts and a full garage to rebuild diffs so we can provide tech assistance to whoever needs it. It doesn’t matter what product they’re running; Jason and Brian were there to fix it. Yukon saved team after team that had broken parts, limited drivetrain experience, and/or no replacement. We get them back on the track saving them from what looked like a long drive home. Ask anyone out there, and they’ll tell you it’s about the racing. The more cars in the race the better. Teams and competitors are friends and willing to help, yet fiercely competitive behind the wheel. When it’s the toughest race in the world, your parts have to be good. Better yet, your parts have to be great! Many manufacturers try King of the Hammers one year and are never seen again. The cars run the desert at speeds of 140 mph and hit boulders and dry waterfalls taller than the walls in your home. Yes, things break, but every year we’re back and the calls keep coming for our parts.

Ian "Big Tire" Johnson Spin Free Installation Video

Yukon Spin Free Kits Freewheeling in the Name of Fun and Efficiency Ian Johnson, the host of the TV show “Four Wheeler” on the MotorTrend Network, runs through all the details involved in installing a Spin Free Kit in the accompanying video. The four-wheel-drive systems on some Dodge and Jeep applications are engineered to turn the front axles and transfer case gears when the vehicles are in two-wheel drive mode. This is wasteful on two fronts. First is the wear and tear factor… which is complicated by the fact that these systems feature non-serviceable, failure-prone bearing assemblies. Then there’s the negative impact all the energy used turning the front drivetrain has on fuel economy. Yukon Spin Free Kits swoop in like a superhero to save the day by allowing the front drivetrain to freewheel. These kits replace the failure susceptible and expensive factory unit bearings with serviceable tapered bearings and races. The result is not only a design which is easier and more economical to maintain, but one that offers significant increases in fuel efficiency because mpg-stealing parasitic drag in the front drivetrain is reduced. Each Spin Free Kit includes new wheel hubs, spindles, high-strength Yukon 4340 chromoly outer axles, Yukon Hardcore premium locking hubs, high-quality bearings and seals, and all the hardware needed for installation. Kits are accompanied by a limited lifetime warranty against manufacturing defects for as long as you own the vehicle. Wasted effort is frustrating. Unnecessary wear and tear and costly repairs are frustrating. Sacrificing fuel efficiency is frustrating. Yukon Gear & Axle Spin Free Kits relieves the frustration and makes your rig less expensive to maintain while allowing it to run longer between fill-ups. It’s a win-win. About Ian Johnson A former high school auto shop teacher, Ian first hit the big time in 2005 as part of Spike TV’s Powerblock weekend programming. Ian co-hosted the popular “Extreme 4x4,” a hardcore how-to show that highlighted the building and modifying of off-road vehicles. After the Powerblock was cancelled in 2013, the show transitioned to Xtreme Off Road (XRO) on Paramount’s Power Nation programming block. Ian left XRO in 2017. He appeared briefly on “Big Tire Garage” before manning the helm of the highly successful “Four Wheeler” show when it debuted in 2019. Like his TV segments, this installation video goes full-tech as Ian highlights all the critical steps with enthusiasm and depth as only he can do. With his big hair and big fabrications skills, Ian is a well-known personality in the off-road industry. Check it out.

Positraction Chatter

When looking for great off-road traction an aggressive positraction is one of the most popular ways to go. But, when driving on the street every day that great off-road posi may be annoying. I have found that it is very difficult to make a positraction work really well off-road and still not chatter during every day driving. Many say that they can do it but my question is can they do it consistently without any customer complaints? Positraction function has been described well by many before me so I will skip that for now. I use the words “positraction” or “posi” as generic terms for all limited slip differentials (not including lockers). Posi chatter happens when there is a lot of friction in the clutches. The friction causes the clutches to bind during a turn and twist the axles. Then the clutches let go and the energy stored in the twisted axles is violently released shaking the whole vehicle. It is kind of like a bomb with energy stored in the twisted axle instead of being store in an explosive. Posi slip happens when there is not enough friction in the clutches and they do not hold when they are needed. Sometimes this can be helped by applying the brake or parking brake lightly in order to add resistance load to the carrier assembly which increases the clutch loading. Even with aid from driving technique a slipping posi is disappointing when off-road and really disappointing when stuck with one wheel still having good traction. The ultimate positraction would slip during every day driving and then sense that one wheel is slipping a lot relative to the vehicle speed and then apply more friction. Many manufactures have attempted to achieve this through many different types of positractions. Every time I see someone promote the final solution they find a way to upgrade it a year or two later and promote the replacement as the final solution. For those of you who are really serious about off-road I suggest getting some sort of locker but that can be left for another time. Popular Resources: New Gear Break-In Properly Setting Preload with Side Adjusters Size Matters

JL Metallurgy Overview

New Jeep JL platform provides design challenges in the automotive aftermarket The new JL platform from Jeep quickly became one of the significant introductions from carmakers in many years. Like every other Jeep platform, opportunities for aftermarket manufacturers to modify, lift, and design came quickly after the introduction. For aftermarket drivetrain engineers, working on the new Jeep JL platform provided with design challenges when it came to the ring and pinions. The JL launched with a new set of differentials including the D44JL Rear (M220), D44JL Front (M210) & D35JL (M200). Factory Engineers had designed the ring & pinions for higher efficiencies. Whether this had to do with increased mileage requirement or powertrain revisions, differential modifications were required throughout the platform. From a design perspective, this factory revision denotes a decrease in the hypoid offset from previous JK designs resulting in a smaller pinion head diameter with increased loading on the teeth. Stronger alloys, most notably an increase in the nickel content, are required to handle the increased loads. Most aftermarket manufacturers recognized the design change, that was the easy part. Only Yukon recognized that the design change required improvements to the metallurgy as well. Recognizing the significant changes in the OE gears for the JL platform, Yukon Engineers examined countless material and heat treatment options to effectively deal with the new hypoid offset. Yukon realized the need to manufacture the JL ring & pinion line with a premium higher strength 4320 material to hold up to the abuse and provide even higher strength than the JK. A year later, after testing Yukon against other aftermarket brands, it appears that Yukon was the only aftermarket company to move to the higher strength material and produce the strongest aftermarket gears associated with Jeep JL line.

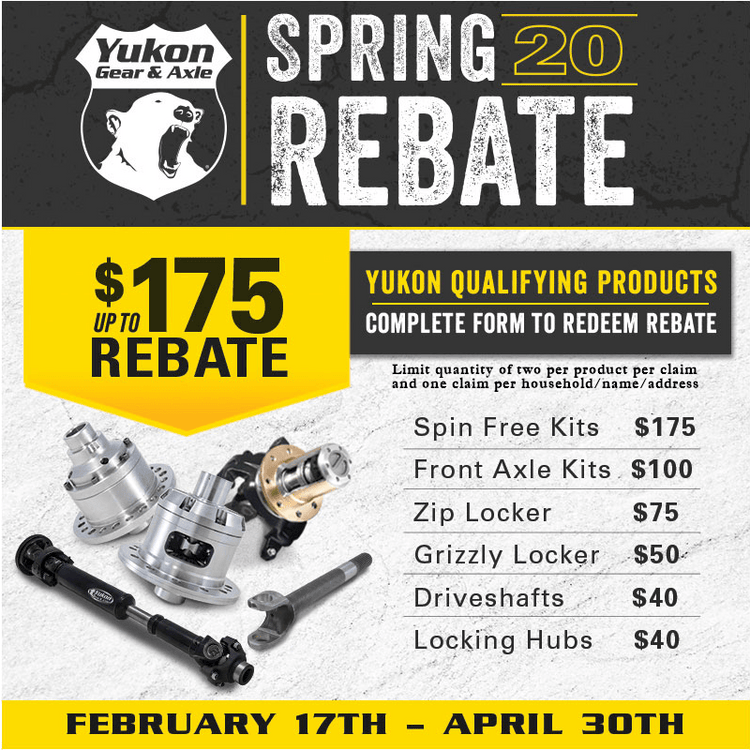

Yukon Spring Rebate 2020

Online Form Mail in Form Item List Yukon Grizzly Locker – $50 Rebate Yukon Grizzly Locker – $50 Rebate Tear it up with our Grizzly Locker’s heat treated 8620 & 9310 Steel internals designed to dominate extreme torque and shock load Premium alloy steel and nodular iron cases are designed for performance quality strength with minimal deflection Large inner-clutch teeth are stronger than back-cut designs by 350%, allowing great resistance to shock load or broken axle failures Yukon Spin Free Kit – $175 Rebate Yukon Spin Free Kit – $175 Rebate Yukon’s top of the line Hub conversion kit uncouples your wheels from the front axle, letting it operate more efficiently, reducing drag for a smoother ride and boosting fuel economy Replace your inaccessible, worn and vulnerable factory unit bearings with our complete Yukon Spin Free kit that comes with our toughest outer axles forged from 4340 Chromoly Steel, and forged hubs on most applications. Clean and sleek, this kit includes Yukon Hardcore Locking Hubs that let you engage into 4WD to play hard and easily disengage for the road back home Yukon Driveshafts – $40 Rebate Yukon Driveshafts – $40 Rebate Provides the highest quality performance driveshafts Double cardan joints and high strength steel allow for increased articulation to accommodate lifts, reduced vibration, and improved durability on the trails 1310 – 1410 U-joints sizes available for high strength Available for JK, JL, and JT Jeep models Yukon Front Axle Kit – $100 Rebate Yukon Front Axle Kit – $100 Rebate Next-level strength and toughness from 100% 4340 Steel that undergoes Yukon’s stringent proprietary heat treatment process and in-house torque testing Tight tolerance yoke-end is the trick to a properly fitted u-joint that won’t vibrate or loosen Smooth and precise bearing journals are the secret to maximizing bearing and seal life, thanks to Yukon’s unique surface finishing treatment Yukon Zip Locker – $75 Rebate Yukon Zip Locker – $75 Rebate Yukon’s most impressive locker yet, forged from an entirely steel case to protect the internals with minimal deflection and maximum strength Air-operated intelligently designed locker, compact air compressor sold separately Bevel gears are optimized using our specialized design software to create a stress balanced tooth design that promotes superior strength and eliminates weak links Designed to handle extreme torque and shocks loads, heat treated 4320 & 9310 steel bevel gears and lock ring let you unleash power and stay locked until you disengage the locker Yukon Hardcore Locking Hubs – $40 Rebate Yukon Hardcore Locking Hubs – $40 Rebate Built for extreme off road, pulling, and performance featuring chromoly internals and steel construction for ultimate durability & strength Manual locking hubs provide the selectability between open axles for improved gas mileage, and reduced wear, and locked axles for maximum traction and grip when off-roading or towing Engagement comes from just a 1/3 turn of the all-steel, low-profile bezel to reduce impact with obstacles Proprietary coating on the locking gears for decreased friction & long life