Don’t Throw Away That Model 20 Rearend Yet!

The AMC model 20 rearend has been getting a bad rap for years. The two-piece axle design that AMC used in most Model 20’s is about as sturdy as using dental floss for a tow rope. For reasons of economy or otherwise, AMC stuck with its two-piece design axle right up until the very end. There are some applications that come with the one-piece axles stock, but they are few and far between. Given these drawbacks, you are probably thinking it is time to retire that Model 20 rear end. Not so fast. The two-piece axles are a weak link that can easily be overcome. Also, the ring & pinion in a Model 20 is actually larger than a Dana 44, so this larger gear can take more abuse and holds up well with tall tires. There are many sources for high quality one-piece replacement axles that are superior to the original design. I prefer designs that use Timken SET9 axles bearings. These high quality bearings do not need to be adjusted for proper end play. They hold up very well with oversized tires, and replacements are readily available if they become damaged by rust or wear. For those of you to whom cost is no barrier, Warn Industries now makes a full float axle kit. These high quality kits use forged 29 spline axles and include all of the hardware to make you M20 a full float rear end. As far as axle strength goes, the M20 axles are 29 spline and are virtually as strong as the 30 spline D44 axles. I have seen axles break in both rearends, so neither is completely indestructible. However, both are relatively strong and hold up well to all but the severest conditions. Upgrading to stronger axles is only the beginning of a strong rear end. I also recommend a good positraction or locker and the right gear ratio. You may say, “I told you this diff is a loser,” but any other design will also need a good traction differential and the right ratio. For occasional off-road use, the stock Trac-Lok limited slip may work, but I seldom recommend it due to its wimpy clutch design. Auburn Gear now makes a strong, aggressive limited slip that works well off-road and drives fairly smoothly on pavement. At one time, AMC used Powr-Loks in some passenger car applications. If they can still be found in wrecking yards, these work great for off road. There are also several locker available: Lock-Rights, EZ Lockers, ARB Lockers, and of course, the Detroit Locker. I personally like the strength and ease of use of the Detroit Locker. However, the ARB Airlocker is smoother for street driving, and the Lock-Right and EZ Lockers are easier to install. Don’t Throw Away That Model 20 Rearend YetWhen it comes to gears, the Model 20 ring & pinion gears are larger that those of the Dana 44. The D44 is ring gear 8.5″ in diameter and the M20 is 8.875″ in diameter. The pinion shaft on the M20 is also much larger and supports the pinion teeth very well under heavy loads. The only drawback of the M20 ring & pinion is the lack of numerically high ratios available. To my knowledge, 4.56 is the lowest (highest numerically) ratio available. A complete list of ratios that are available includes: 2.73, 3.07, 3.31, 3.54, 3.73, 4.10, and 4.56. So, yes, there are some shortcomings when using the Model 20 rearend. Nevertheless, when all is considered, I still believe that the Model 20 is a good choice in most situations, and the bad reputation earned by its weak axles is not reason enough to pitch the entire rear end.

The Randys Advantage

RANDYS ADVANTAGE RANDYS Worldwide is renowned for offering the highest quality aftermarket drivetrain and differential parts with USA Standard OEM replacement parts, Yukon Gear high performance parts, and Zumbrota Drivetrain complete manual transmission, transfer case, and axle assemblies. QUALITY Engineered in our Everett, Washington headquarters, RANDYS Worldwide uses state-of-the art design, manufacturing, and testing processes, backed by two in-house quality labs to ensure every item meets exact specifications & quality standards. WIDEST SELECTION With 19,000 part numbers, our parts span everything from 1948 to present covering both domestic and foreign vehicles. Have a vintage muscle car? Check, we have parts for that. Have a 2019 Jeep Wrangler Rubicon? Check, we have parts for that too. Toyota 4Runner? Suzuki Samurai? Xterra? Check, check, and check. From vintage to modern, restoration to high performance, low riders to rock crawlers, as long as your vehicle has a differential, we have the drivetrain parts it. HIGH FILL RATE + FAST SHIPPING RANDYS Worldwide boasts an incredibly strong distribution network throughout the US and global shipping partners. In addition, RANDYS 7 fully stocked warehouses deliver 1-2 day shipping nationwide. What's more, 2 day shipping covers 95% of the USA. SERVICE RANDYS Worldwide knows what it takes to keep our products in vehicles on and off road. We start with impeccable parts quality, deep technical expertise, and exceptional customers service to keep it all together. Our service level means that we far surpass the competition, supporting our customers to ensure that the parts they purchase are backed by industry forward quality, warranties, and technical support. It all Starts with Quality RANDYS WORLDWIDE | THE DIFFERENTIAL EXPERTS In the world of differential excellence: technology, quality & product knowledge make the difference in choice. Learn how RANDYS works to bring you the best differential products in the industry. Widest Selection of Drivetrain Parts, Kits, and Complete Assemblies OEM Replacement and Performance Parts Offering performance limited slip differentials, mechanical lockers, air operated lockers, spools, axles, and ring and pinions in a large array of ratios. Small Parts Axle bearings, seals, studs, u-joints, washers, spacers, crush sleeves - we have what you need to finish the job. Driveshafts From OEM replacement to performance with multiple options and varieties of styles, we have the driveshafts to suit your needs and budget. From CV to slip-yoke to double cardan and all other styles, RANDYS has you covered. Transfer Case Components & Complete Units Need a component part? No problem. Need a completely re-manufactured, state of the art unit? We have those too. Our transfer case parts and full builds are made with the highest quality processes that surpass industry standards. Transmission Units & Parts Offering a full breadth of Standard Transmission (Manual Transmission) components and complete high quality units. Complete Axle Assemblies Why rebuild when you can save time and just install a high quality remanufactured axle assembly. Complete with all new internals, seals, bearings, and everything you need to get back on the road in a jiff.

Wholesale Onboarding Packet

Ford 9 Inch Differential Information

The Ford 9″ axle is a semi-floating, drop-out with a GAWR up to 3600 lbs and is one of the most popular axles in automotive history. Ford began production in 1957 and stopped production in 1986 though many after market companies still produce this rear end. FEATURES The Ford 9″ has a stamped housing with axletubes welded on each end and nothing else. This makes the rearend easier to service because of its removable centersection that houses the gearset. This removable gear case houses a differential unit that the ring gear bolts onto. What sets the Ford 9″ apart from other high performance and heavy duty solid axles is that access to the differential gears is not through the rear center cover, which is welded to the axle housing, but through the center cover on the pinion side of the axle where the drive shaft connects. FORD 9″ BENEFITS The Ford 9″ has a number of benefits over its competition, here are just a few of them.In a Ford 9″ swapping gears is supremely easy as it has a removable third member. This is even more important if for dual purpose vehicles. A Ford 9″ also makes axles easy to install or remove as Ford designed the axle to slide out by yanking four bolts per axle flange for the 28- and 31-spline axles. An added plus for the Ford 9″ is an internal rear-pinion support that also supports the gear end of the pinion to limit gear deflection under high torque loads. Ford improved tooth contact in the Ford 9″ by locating its pinion gear lower on the ring gear. This strengthens the rear end assembly but results in a minor loss of power to drive the gears. A Ford 9″ can save you money if the worst should happen. At some point no matter what axle you buy, that axle will break if you are doing something rough. With a Ford 9″ if the axle breaks inside the housing, the axle retainer keeps the axle in place, where in other types the axle would slide out potentially causing massive sheet metal damage. The Ford 9″ also has the widest variety of ratios on the market, so no matter what you have chances are excellent a Ford 9″ can work with it.

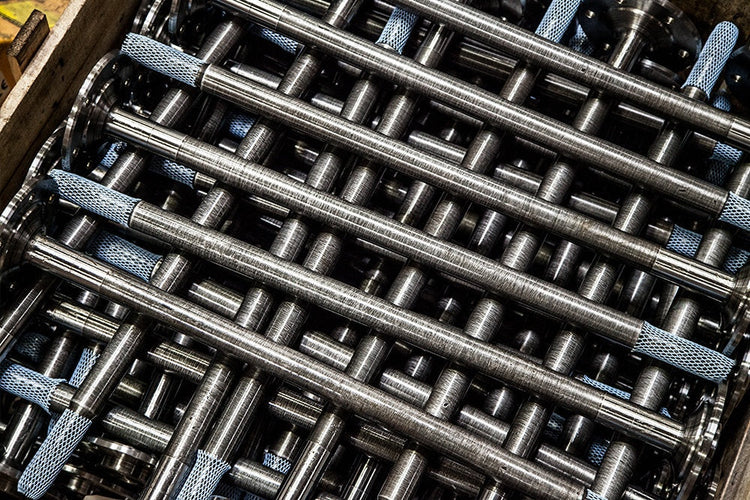

Tech Tidbit: Common Steel Groups for Axles

Typically, steel is rated by the SAE or the ASM according to its particular elements. Proven and standardized “recipes” are issued a four-digit number. The first two signify the steel group, i.e. carbon steel, nickel-chromium-molybdenum steel, etc. The second two indicate the carbon content in hundredths of a percent, which is variable according to end use. 10XX, 11XX, 12XX, 15XX = The carbon steel group. Most standard OEM axles are 1040 grade. OEM axles are generally heat treated to 40 Rockwell in the center with the outer layer at 55-60 Rockwell to a depth of about .180 inch. These grades all carry from 1.00-1.65% manganese. The industry differentiates these steels by their carbon content, i.e., “low carbon” and “high carbon” steels. The last two digits “XX” indicate the carbon content of the steel. A “30” indicates 3% carbon, “40” indicates 4% carbon, and so on. 13XX = This manganese steel group contains 1.45-2.05% manganese. If it contains 1.6-2.05% manganese, it can be called an alloy steel. This grade is used by aftermarket axle builders because the high manganese content allows for more flexibility during the heat treating process. Some 15XX steels have 1.6-2.05% manganese. 41XX, 43XX, 47XX, 86XX = The nickel chromium-molybdenum group. An alloy containing .65-.95% chromium, .2-.3% molybdenum and 1.55-2.0% nickel. Chromium increases hardness and the elastic limits (when the material is quenched), as well as increasing corrosion resistance. Molybdenum and nickel also increase hardness. “H” Rated = There is a whole range of “H” rated steels that will match the composition of the standard type, such as 1340, but will contain a measure of silicon. Silicon comes from quartz and sand and when mixed into steel it adds a measure of hardness and can improve or increase the heat treating options. 1340H, for example, has .15-.30% silicon. “M” Rated = These are modified steel, where the “recipe” of a rated steel has been given slight enhancements to improve or alter its characteristics. Two are commonly seen in the axle world, 1541M and 4340M (a.k.a., 300M). Comparison of Steel Properties* SAE Grade Tensile Strength Yield Strength 1040 120,000 psi 106,000 psi 1050 162,000 psi 146,000 psi 1541H 181,000 psi 164,000 psi 4340 228,000 psi 210,000 psi *Typical, as used in the actual product, including all heat treatments. Some specific recipes might be higher or lower. This represents an industry average. Popular Resources: Limited Slips: Gov-Lock vs. Yukon Dura Grip Identifying Borg Warner Transfer Cases Limited Slips vs. Differential Lockers vs. Spools