How to set Ring and Pinion Backlash

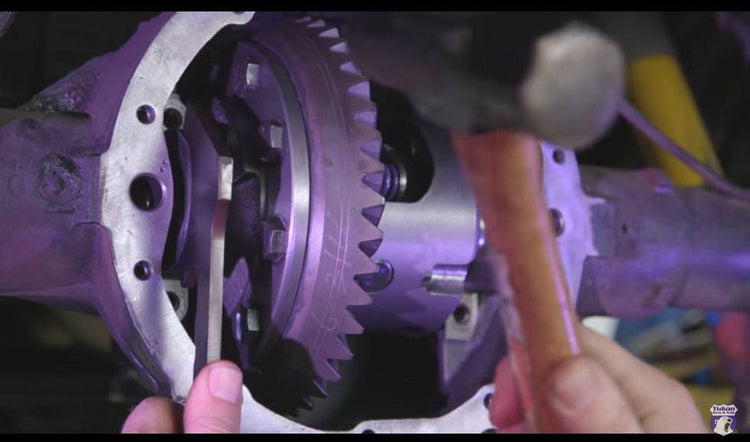

Once you have installed and set the proper pinion gear depth with either a pinion depth gauge or by the pattern revealed when using a gear marking compound, it’s time to address backlash. Ring and pinion backlash refers to the amount of play between the gears. An abundance of play can become a factor on vehicles that are heavy or rigs that tow or haul hefty loads. Loose tolerances between the gears can cause binding under acceleration and deceleration and lead to noise, overheating, and ultimately gear and/or bearing failure. Shim For The Win It’s always a good practice to start the process with your factory carrier shims. Make sure they’re clean and measure them in three places to ensure a proper fitment. Add some oil to the outside of the shims to allow for easier installation. Start with the right-hand side to prevent tooth binding with the pinion and drive each shim completely into place. Then install the left-hand shims and your carrier should be in place. Dialing It In Once fully seated, install and tighten down the carrier pads. Always install and tighten the right side first. With the carrier assembly installed, attach your dial indicator with the plunger at a 90-degree angle from the face of the ring gear teeth. Gently rock the carrier back and forth to measure your backlash. You’ll want to do this in three separate locations on the ring gear to check for runout. If the backlash is too tight, move the carrier away from the pinion by adjusting the carrier shim. If the backlash is too wide, adjust the carrier toward the pinion. When adjusting the backlash, a rule of thumb is 10 thousandths of carrier shim adjustment will result in around 7 thou of backlash adjustment. Rock the carrier back and forth until little to no free play is evident. To see how setting backlash works check out the accompanying video.

JL Metallurgy Overview

New Jeep JL platform provides design challenges in the automotive aftermarket The new JL platform from Jeep quickly became one of the significant introductions from carmakers in many years. Like every other Jeep platform, opportunities for aftermarket manufacturers to modify, lift, and design came quickly after the introduction. For aftermarket drivetrain engineers, working on the new Jeep JL platform provided with design challenges when it came to the ring and pinions. The JL launched with a new set of differentials including the D44JL Rear (M220), D44JL Front (M210) & D35JL (M200). Factory Engineers had designed the ring & pinions for higher efficiencies. Whether this had to do with increased mileage requirement or powertrain revisions, differential modifications were required throughout the platform. From a design perspective, this factory revision denotes a decrease in the hypoid offset from previous JK designs resulting in a smaller pinion head diameter with increased loading on the teeth. Stronger alloys, most notably an increase in the nickel content, are required to handle the increased loads. Most aftermarket manufacturers recognized the design change, that was the easy part. Only Yukon recognized that the design change required improvements to the metallurgy as well. Recognizing the significant changes in the OE gears for the JL platform, Yukon Engineers examined countless material and heat treatment options to effectively deal with the new hypoid offset. Yukon realized the need to manufacture the JL ring & pinion line with a premium higher strength 4320 material to hold up to the abuse and provide even higher strength than the JK. A year later, after testing Yukon against other aftermarket brands, it appears that Yukon was the only aftermarket company to move to the higher strength material and produce the strongest aftermarket gears associated with Jeep JL line.