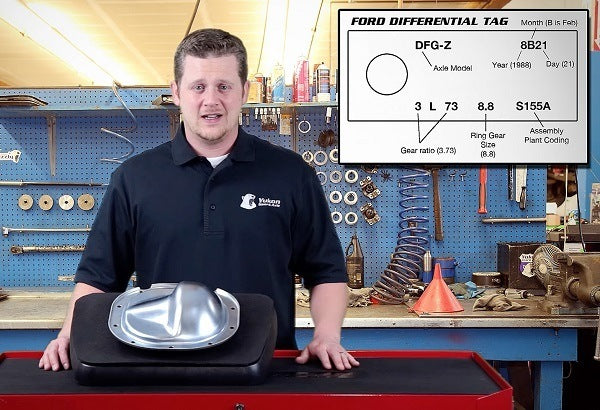

Decoding Differential Tags - Video

Auto manufactures have made it possible to glean basic but useable differential information by means of tags, stickers or stampings on the differential. The tags are usually affixed to the pumpkin by a diff cover bolt and stickers can be on the housing or axle tube close to the housing. The “direct from the source” aspect of this information makes it hyper accurate, overriding any confusing make, model, engine, and transmission information mash-up. No late night research needed. It’s all right there, straight from the manufacturer. The accompanying videos outline what info is on Ford and GM tags and what it means to you.

How It Works: Dropout vs. Carrier-Type Differentials

While every differential housing performs the same basic job—holding the gears that turn engine power into forward motion—there are two key designs you’ll find out there: dropout differentials and carrier differentials. Dropout Differentials Dropout differentials—also called third members—can be identified by their removable front center section. The ring-and-pinion gear set lives inside a carrier assembly that can be easily removed or “dropped out” for service or gear swaps. The legendary Ford 9-inch is the most famous example of a dropout differential, but GM, Toyota, Chrysler, and others have used them as well. The ribbed housing is a quick giveaway that this is a Ford 9-inch. Common Dropout Designs The Ford 9-inch has countless aftermarket configurations, but it’s not alone. Toyota’s lineup includes the 7.5”, 8”, 8” high-pinion, 8” clamshell, 8.5”, T100 IFS, and several 9”, 9.5”, and 10” variations. Mopar fans know dropout-style diffs as banjo-style differentials, with the Chrysler 8.75” being the standout example. Dana has also built many dropout-style units that show up across different makes and models. Fun fact: in some circles, a front-loading dropout differential is called a pig-style diff, and across the pond, the ring gear is known as a crown wheel. No matter what you call it, they all get the job done. Why Choose a Dropout Differential? The main advantage of a dropout differential is ease of gear swaps. Because the entire gear case can be unbolted and removed, all the setup work—ring and pinion installation, backlash adjustment, and pattern checking—can be done comfortably on a workbench instead of under the vehicle. That means faster swaps, easier adjustments, and a cleaner install overall. Carrier Differentials Carrier differentials, on the other hand, are identified by their rear cover. To access the ring and pinion gears or other internals, you remove the cover on the back of the housing. GM’s well-known 10-bolt and 12-bolt designs fall into this category. In British terminology, these are called Salisbury differentials. If you can see the gears from the back, you’re looking at a carrier-style differential. Strengths of Carrier Differentials Carrier-style diffs are extremely common and have a few key strengths. Inspection and troubleshooting are easier—just pop the rear cover and you can see inside. No need to remove the entire center section to diagnose a problem. (Some aftermarket dropout diffs now include rear inspection covers to address this advantage.) One drawback for off-roaders, however, is the exposed diff cover. On rocky trails, a stock stamped-steel cover can get peeled back or punctured by a rock or tree stump—leaving your gears vulnerable. Protect Your Investment with Yukon Hardcore Diff Covers That’s where Yukon Hardcore Performance Diff Covers come in. Built from thick-walled nodular iron, these covers protect lockers, gears, and axles from impacts and housing flex. Each Yukon Hardcore cover features a durable powder coat finish, a magnetic drain plug, a premium gasket, and high-strength fasteners for a clean, reliable install that’s ready for anything the trail can throw at you. Shop Yukon Diff Covers Know Your Setup Understanding the difference between dropout and carrier differentials will help you make smarter choices when upgrading or servicing your drivetrain. Whether you’re re-gearing, installing a locker, or just protecting your investment, knowing how your diff works—and what upgrades it deserves—makes all the difference. Shop Yukon Re-Gear Kits

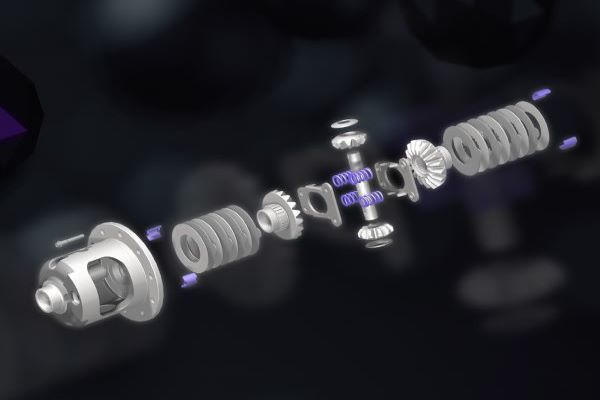

CÓMO FUNCIONAN LOS ENGRANAJES SATÉLITALES DEL DIFERENCIAL

Los satélites en el diferencial son protagonistas estelares. También conocidos como engranajes de los satélites, usualmente cuatro que se acoplan con dos ruedas de forma cónica denominados planetarios. Engranajes Satelitales Son los engranajes que se encargan de realizar la función diferencial. Los planetarios están unidos de forma rígida a los palieres, que transmiten la fuerza a cada rueda, los satélites giran libremente sobre su eje. Uno de los planetarios siempre está unido a la corona, estando conectado al otro planetario mediante el engranaje de los satélites. Estos engranajes se encuentran agrupados dentro del núcleo ¿Cuál es la función del engranaje? Los engranajes de los satélites y los engranajes laterales del diferencial toman la energía de la rotación del eje de la transmisión y ayudan a redirigirla hacia los ejes y los neumáticos. Más importante aún, también juegan un papel clave al permitir que las llantas neumáticos giren suavemente a diferentes velocidades cuando el vehículo está haciendo algún giro. Los engranajes están en problemas Cuando los engranajes de los satélites se rompen producirán un ruido o un golpe muy fuerte especialmente cuando el vehículo está haciendo algún giro, porque la diferencia en las velocidades de las ruedas causa la vibración. Por lo general, cuando estás conduciendo en dirección recta no se escucha ningún ruido porque los engranajes de los satélites permanecen inmóviles dentro del carrier. Pero, si verdaderamente estos engranajes satelitales están malos harán ruido incluso cuando vayan en línea recta. Cuando escuche un fuerte ruido salir del diferencial piense en la formación de partículas metálicas que circulan por toda la unidad, que por lo general daña primero los rodamientos vulnerables. Entonces, el ruido significa problemas. Quizás en algunos casos, el daño pueda no ser el propio engranaje. Cuando los engranajes satelitales están en movimiento estos giran libremente sobre su eje, especialmente cuando el vehículo está haciendo un giro en una esquina. Pero hay situaciones que pueden causar un giro excesivo y el resultado puede ser un eje dañado por el calor. Un escenario común es quedarse atascado en el barro o la nieve y hacer patinar las llantas tratando de liberarse. Cuando esto sucede, los engranajes satelitales pueden girar en el eje transversal tan rápidamente que el aceite del diferencial se disipara lo que resulta en un desgaste de metal contra metal. En casos extremos, el eje transversal y el engranaje se calientan tanto que se funden entre sí, a veces hasta el punto en que se peguen entre sí como si fueran soldados por el calor. Un daño como este no solo puede dañar el grupo de los engranajes satelitales, sino también destruir el carrier y el conjunto de engranajes de piñón corona. Reemplazo del de los engranajes satelitales Al reemplazar los engranajes satelitales de hecho estás reemplazando tanto los engranajes de los satélites como los engranajes laterales. A lo largo del kilometraje estos engranajes se desgastaran por lo que reemplazar nuevos engranajes de satélites con los engranajes laterales originales puede causar un desequilibrio. Los juegos de engranajes satelitales de la compañía Yukon Gear & Axle y USA Standard Gear incluyen dos engranajes laterales, dos engranajes de piñón, un eje de pasador transversal, un pasador de rodillo y arandelas. La instalación es relativamente sencilla. Para ver algo más profundo, vea el video de instalación adjunto del canal de YouTube. Contacta con nosotras en 866-631-0196 comprar kits de engranajes de araña

Tales From The Tech Line: Re-Gearing A Jeep JLU Wrangler With 35-Inch Tires

Q- Hello Yukon Team, I have a 2021 Jeep Wrangler JLU Sport S. I was able to retrieve my build sheet based on VIN and I have a M186 front axle and M220 rear axle with stock 3.45 gearing. I have a limited slip diff in the rear and open diff in the front. I recently completed a 3.5-inch suspension lift and added 35 x 12.5R17 tires. As you probably are aware this has made the Jeep pretty gutless. I should also mention I have a six-speed manual with the 3.6-liter Pentastar V6 engine. My goal is to use the Jeep as a daily driver and the odd Overland trip and off-roading here and there throughout the year. I am under the impression 4.56 gears are a good fit for my application. My questions for your team are: Is a 4.56 gear set right for my application? Keeping in mind it’s a daily driver with overlanding consisting of long distance driving on the highway to the trail then mild to moderate off-roading. Do I require new differential carriers to go with the new ring and pinion sets for the increase of gearing from 3.45 to 4.56? Or will my existing differential carriers work with the 4.56 gears as well. Do you make a locker that fits a front M186 axle? Do you make a 4.56 ring and pinion gear set for both the M186 and M220? I appreciate your time and guidance on these newbie questions. I look forward to your response and any further knowledge or guidance you can share with me. Regards, Brandon Williams A- Hey Brandon, Brandon, you are correct, the 3.6-liter “minivan” motor is no torque monster by any stretch of the imagination, but it does run fairly well when allowed to rev a little. I’d say engine speed in this application is actually advantageous, it allows the motor to get up into a rev-range where not only does it make more torque naturally, but the volumetric efficiency improves and BSFC comes down. Jeeps with automatic transmissions will downshift very easily to try to keep the engine in this range, but manual trans versions must be driven like a four-cylinder, rather than trying to lug it like a V8 or a diesel. That being said, everything that Jeep does revolves around meeting corporate average fuel economy (CAFE) standards in a test environment–not in the real world. So, any aspect of performance that impacts CAFE is hyper optimized for that singular, fuel efficiency goal. Why do I bring that up? Because many people attempt to build with comparing it to stock rpm or stock road characteristics… using OE performance as a baseline results in disappointment time after time. My recommendation for a manual trans equipped Jeep JL on 35’s is 4.88’s, you can see in the chart below, this works out to just a hair over 2,000 rpm at 60 mph. This is only about 350 rpm higher than stock at cruising speed, but it gets the motor up where it can compensate for the additional wind load, rotating mass, and rolling resistance produced by your modifications. A lot of people worry about loss of drivability on the highway, or excessive cruising rpm on cross country trips. This really is not the case. In this next chart, to can see rpm vs speed in each gear, and that realistically, even crossing Texas, Montana, or any extended road trip where vehicles typically do 85-90 mph, you’re still below 3,000 rpm, and if the worry is maintaining speed on hills like the continental divide or any challenging ascent, if power is needed, fourth gear is still useable at highway speeds. You mentioned overlanding, if you plan to build this extremely heavy, and/or tow a tent trailer or the like with it, you may even choose to go deeper than 4.88s, in fact, 5.38s are not uncommon for someone planning to tow on 35s. Looking back to the first chart, you can see at cruise speeds, 5.38s are still only turning 2,200 rpm and change. An additional benefit? The Jeep should actually feel “sporty” if I dare to use “Jeep” and “sporty” in the same sentence. Hopefully this info helps to clarify some of the misleading internet half-truths. As far as parts, yes, we offer complete packages for what you need, new carriers are not required, but if looking for traction upgrades they will be needed. For a daily driver/moderate off roader, I’d lean more toward one of our helical limited slips up front. They operate absolutely seamlessly, and unlike a locker LSDs create zero on-road drivability issues. So, if you foresee the need to travel in adverse–snowy/icy conditions in 4-High, lockers will get you into more trouble than they’ll get you out of. The two links below will get you everything you need to get the job done, short of fluids, tools, and beverages. Complete Yukon 4.88 Ring And Pinion Gear Set & Instalation Kit USA Standard Gear Spartan Gear-Driven LSD For Dana 30 Feel free to reach back out if you have any further questions. Gus Pyeatt, Tech Support Specialist

How It Works: Yukon Dana 30 CAD Delete Kit

What is CAD? What is CAD? It’s not short for Cadillac… In this case it’s not the acronym for Computer Aided Design… For our purpose CAD stands for "Central Axle Disconnect." At its core, the Yukon Dana 30 CAD Delete Kit blocks off the vacuum actuated engagement of four-wheel drive in Dana 30 differentials. Select Jeep vehicles produced from 1984 to 2001 are equipped with the automaker’s reverse rotation Dana 30 differential that’s outfitted with the Central Axle Disconnect (CAD) system. The system components, located on the passenger-side axle tube, consist of a two-piece splined shaft and a coupler that a vacuum-operated shift fork actuates to connect or disconnect the axle, which engages or disengages four-wheel drive. Dana 30 Heritage The Dana 30 has been the go-to front diff for the Jeep Wrangler since the model’s Jurassic Period… CJ-5 models of the early 1970s. Available in high- and low-pinion versions as well as standard and reverse rotation versions, the Dana 30 is an important building block in the Jeep hierarchy. There are tons of aftermarket parts for this differential and spares waiting for rescue in junkyards across the country. CAD Versus The Elements Time is no friend to the CAD system. The vacuum lines can crack, the vacuum motor can fail, or the system can be compromised in another manner, and cause the Jeep to be stuck in two-wheel-drive… that’s no fun. Further, the two-piece axle is not as strong as a one-piece design. Fortunately, the stronger and more reliable one-piece axle from a TJ or ‘non-disconnect’ XJ are direct swaps. The catch… sealing the housing post-swap. Yukon To The Rescue Enter the Yukon Dana 30 CAD Delete Kit. It consists of a disconnect housing blocking plate, gasket, and inner axle seals that will accommodate a one-piece axle design. Yukon Dana 30 CAD Delete Kit Applications 1984 - 2001 Jeep Cherokee XJ 4WD 1984 - 1998 Jeep Cherokee XJ Sport 4WD 1986 - 1992 Jeep Comanche MJ 4WD 1984 - 1991 Jeep Grand Wagoneer ZJ 4WD 1993 Jeep Grand Wagoneer ZJ 4WD 1987 - 1995 Jeep Wrangler YJ 4WD End Of The Trail The Dana 30 has been around since the prehistoric days of the Jeep brand… and it’s not going anywhere. Neither is Yukon Gear & Axle. We have a vast inventory of replacement parts that will keep Dana 30s on the road and performance products that will improve the breed. Happy Wheeling. contact us at 866-631-0196 Shop CAD Delete Kits