Breaking In Your Ring And Pinion

Gear break-in consists of controlled heat cycling of the gear set in a way that properly seasons or hardens the gear’s contact surfaces. It is a series of test drives. These critical first few miles of drive time can be the difference between a gear-melting headache and years of carefree driving. Failure to properly break-in your gear set can result in damaged, failing gears, and a complete re-do. Read this article in Español Once the wrenches have been laid down and the gears have been properly installed with pinion depth, backlash, and preload correctly set there’s still more to do. The break-in process is really important if you want to have your gears last a long time and perform the way you want them to. The First Drive In the first couple of miles you will want these to be in-town speeds, 15 to 20 mph. Drive for 20 minutes or so, let the diff cool off for about a half an hour, and then repeat the process. Next time you drive your vehicle you’ll want to do some freeway runs. Drive about 15 miles, then pull over and let the drivetrain cool down for about 20 minutes and do this for about 45 miles or so. It may seem like a headache, but it is worth it to ensure the gears are broken in properly instead of burning them up and creating a bunch of metal sledge in your differential. Proper Oiling The next important component is to ensure you have proper lubricants. For the first 500 miles run 80W-90 conventional oil, drain it, and then refill the diff. RANDYS recommends a non-synthetic oil if your set-up features a Dura Grip clutch-type limited slip differential. If you’re running a helical LSD or a locker, synthetics are great for those applications. Break-In For Rigs That Tow Towing with your vehicle or using it for extreme off roading adds additional pressure to the pinion and can slightly change its position on the ring gear teeth. This means you are essentially hardening a new spot on the gear. Therefore, we strongly encourage drivers to follow the same break-in procedure while either towing, hauling, or driving off road. Even if you’ve already broken in the gear set with no addition load follow the same speeds and distances of your previous break-in drives. Start with in-town speeds of 15 to 20 mph, cool down, and repeat. Then hit the freeway and drive 15 miles at 45 to 50 mph, cool down, and repeat for 45 miles. Long distance hauling is the killer for any ring gear set as you are constantly generating heat without cooling which will break down the gear oil and burn up the gear surface. This is why we recommend a gear oil change after the first 500 miles. If you want to protect your investment and get the best performance out of your gears, then proper break-in is critical. Following the guidelines outlined here will ensure you get the expected results.

How It Works: Spider Gears - Video

Spider gears are primetime players inside the differential. Also known as satellite gears, spider gears rotate around the side gears in the differential carrier. Side gears may also be referred to as axle gears or planetary gears. To spot spider gears look for the gears with the cross-pin shaft going through them. Read this article in Español What Gears Do The diff’s array of spider and side gears take the rotational energy from the driveshaft and help redirect it outwards to the axles and on to the tires. More importantly, they also play a key role in allowing the tires to rotate smoothly at different speeds when the vehicle is turning. Gears In Trouble Broken spider gears will make a grinding or banging sound when the vehicle is turning because the difference in wheel speeds causes the chatter. You usually won’t hear them when traveling in a straight line because the spider gears remain motionless within the carrier in this instance. But, if they are bad enough, compromised spider gears will make noise even when going straight. When you hear a loud differential think of metal flakes being formed and circulated throughout the unit, usually damaging the vulnerable bearings first. So, noise means trouble. In some cases, the damage may not be the gears themselves. When the spider gears are in motion they rotate on the cross-pin shaft, especially when the vehicle is turning a corner. But there are situations that can cause over spinning and the result can be a heat-scored cross-pin shaft. A common scenario is getting stuck in the mud or snow and free spinning your wheels trying to break free. When this happens, the spider gears can rotate on the cross-pin shaft so quickly that the differential oil is slung away, resulting in metal-on-metal wear. In extreme cases the cross-pin shaft and the gear get so hot that they melt each other, sometimes to the point where they weld themselves together. Damage such as this can not only damage the spider gear set, but also destroy the carrier and ring and pinion gear set. Spider Gear Replacement When replacing spider gears you are, in fact, replacing both the spider gears and the side gears. Over the miles these gears mesh and wear in unison, so dropping in new spider gears with the original side gears can cause an imbalance. Yukon Gear & Axle and USA Standard Gear spider gear kits include two side gears, two pinion gears, a cross pin shaft, a roll pin, and thrust washers. Installation is relatively straightforward. For a more in-depth look, view the accompanying installation video from our YouTube channel. contact us at 866-631-0196 Shop Spider Gear kits

SÍNTOMAS DE DIFERENCIAL DAÑADO. LOS SONIDOS DE LA MUERTE

Si has frecuentado las pistas de competición indudablemente te das cuenta de lo ruidoso que es un hot rod cuando suelta el embrague y luego suelta una carga de engranajes y metal en la pista. En los senderos un vehículo con problemas finalmente se engancha y de repente el torque o el par es demasiado para el diferencial, lo que lleva a la unidad a su desaparición final. Un diferencial también puede tener una muerte lenta y te puede alertar de esa inminente muerte. Un vehículo en movimiento emite muchos diferentes sonidos, la mayoría transmite un estado armonioso. Pero puede haber temblores. A medida que las cosas comienzan a estar mal en un diferencial, hay ruidos que te dan pistas de que algo anda mal y saber qué significan los ruidos te ayudará a determinar cuál es el problema. Con este fin, ofrecemos este resumen de ruidos comunes y su probable punto de origen. Los sonidos de la muerte Cuando estas viajando a velocidades normales de carretera es probable que un sonido como un "zumbido" generado por la descarga a través de la desaceleración se deba a una falla del rodamiento del piñón o una deficiente precarga del rodamiento del piñón. En esta foto se puede ver un verdadero gritón. Una manga aplastada o una falla del rodamiento del piñón provocó que el piñón intentara comerse el carrier/transportador Este mal a menudo se diagnostica como una corona y piñón defectuosa. Bajo una carga positiva cuando se genera un sonido como "gemido" o "aullido", por ejemplo la aceleración está más en línea con el engranaje piñon corona desgastado o defectuoso o un conjunto de engranaje corona piñon que no se ha configurado correctamente. Cuando estas viajando a velocidades superiores a las 20 mph y y usted detecta un sonido “retumbante” que tiende a cambiar de frecuencia mientras el vehículo está girando, puede ser causado por los rodamientos del carrier/transportador desgastados. Pero también podrían ser los rodamientos de una rueda defectuosa. Para confirmar, levante el vehículo en la esquina donde sale el ruido y mueva la llanta. Si hay mucho juego en el aro /llanta lo más probable es que el rodamiento de la rueda sea el culpable. Un sonido como un “chasquido” que se detecta cada pocos pies puede ser un diente roto en su piñon corona. Si recientemente has cambiado tus llantas, comprueba el interior de la rueda para ver si existe un contrapeso expuesto que pueda estar golpeando el cuerpo del amortiguador en cada revolución. Un "golpeteo" más agresivo cuando toma una curva puede ser causado por engranajes satelitales quebrados, una lubricación pobre en los diferenciales de deslizamiento limitado y un embrague gastado en los diferenciales de deslizamiento limitado. Reglas básicas En este proceso, escuchar el sonido es bastante fácil ...rastrear la fuente es la que puede ser complicado. El gran desafío es tratar de diferenciar entre el sonido de un rodamiento defectuoso dentro del diferencial al sonido de un rodamiento de la rueda que está fallando. El sonido es similar. Uno de los factores determinantes es el hecho de que el ruido de los rodamientos de la rueda cambiará con la velocidad de la rueda, pero generalmente no cambiará con las variaciones de carga, por ejemplo la aceleración o la desaceleración, pero el sonido de un diferencial trasero dañado cambiará con la velocidad de la rueda y la carga. Escuche con sus ojos Las fugas también son señales de advertencia. Pueden ser precursores de problemas o el resultado de problemas. Si bien algo de fluidos debajo del vehículo puede ser parte de la condensación del funcionamiento normal, notar goteos rojizos puede ser un signo de una fuga de líquido de transmisión. Un sello o junta dañada puede robarte esa lubricación vital, lo que resulta en partes internas sobrecalentadas y secas así como fallas inminentes. La conclusión aquí es que cualquier ruido que venga de su tren motriz, ya sea que pueda ubicar la fuente o no, es un asunto serio. Rastrear la causa es fundamental para evitar daños más graves y reparaciones más costosas. Para obtener más información sobre los sonidos de la muerte, consulte el video de identificación del ruido de la corona y piñón que lo acompaña. El video está en inglés pero hemos realizado la traducción en español como veras esta en la parte abajo. Fuente original del artículo en inglés: The Sounds Of Death: A Failing Differential Story Gracias por tomarse el tiempo para ver los consejos técnicos de Yukon. Hoy vamos a discutir cómo identificar el ruido de los engranajes del diferencial, dentro del diferencial, hay muchas formas diferentes de acercarse al ruido, pero hoy hablaremos del ruido de los engranajes durante desaceleración. La causa número uno del ruido del engranaje de desaceleración es la pérdida de la precarga del rodamiento del piñón. Cuando sus rodamientos están presionados en su manga de aplastamiento, se sienta entre ellos y crea tensión en los rodamientos internos y externos esa precarga los puede dañar. Por último cuando estás conduciendo por la carretera, una tuerca del piñón se suelta, dentro del espacio de la carcasa tendrás esos rodamientos moviéndose alrededor del eje, esto creará un ruido y desaceleración por permitir a los engranajes moverse mucho por dentro. si se encuentra con esto, tendrá que desarmarlo, reevaluar y de nuevo configurar su precarga además asegúrese de que están dentro de las especificaciones. Gracias por ver este consejo técnico de Yukon sobre cómo identificar el ruido de los engranajes.

How It Works: Lunchbox Lockers

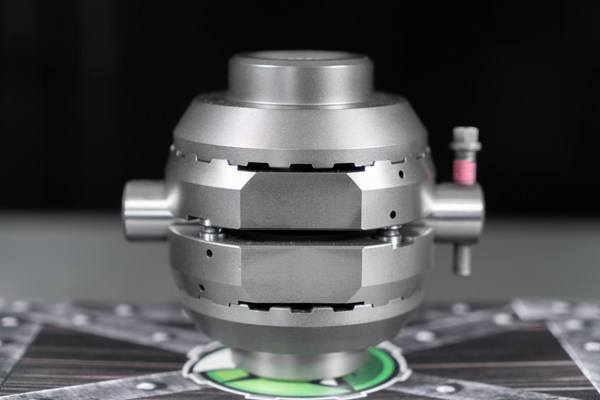

The Spartan Locker, USA Standard Gear’s lunchbox locker, provides game-changing traction at a low cost. A locker physically joins the drive axles together so they deliver an equal amount of torque to each tire, regardless of available traction. Lockers come in two flavors… selectable or mechanical. What are the Different Types of Lockers? A selectable locker is an on-demand unit that the driver activates electronically or pneumatically via a cockpit-mounted button. A mechanical locker is always active, providing traction 24/7. The Spartan Locker and Yukon Grizzly Locker are mechanical. The Yukon Zip Locker is an air locker or selectable locker that uses a pneumatic system for actuation. The Spartan Locker is flanked by a Yukon Grizzly Locker (left) and a Yukon Zip Locker (right). In mechanical lockers, also called automatic lockers, on-throttle driving conditions, where load is applied to the differential, induces locking. Off-throttle situations, where the diff is unloaded, leads to a partially unlocked unit. When the vehicle turns and the two wheels on the axle turn at different speeds, the unit makes a clicking sound as the square-cut side gears move over and past one another. This ratcheting sound can be loud and is why mechanical units may not be best suited for vehicles that spend a lot of time on the street… it all depends on how sensitive your ears are. What’s for Lunch? The lunchbox locker name is a loose reference to that handy mid-day meal carrier we all know and love. Just as you can put a different kind of meal in your lunchbox, the lunchbox locker allows different internals to be put in your differential… the internals being the lunch and the differential carrier being the box portion of the equation. Lunchbox lockers are not a singular component you swap in, but a collection of parts that converts an open differential carrier (and only an open differential carrier) into a mechanical locker. A typical Spartan Locker consists of a pair of drivers, two spacers, two side couplers, four alignment pins, four pre-load springs, a hardened cross-pin shaft, a roll pin, and installation wires. Depending on the differential carrier design, your Spartan Locker could have more or less components in the box. Pros and Cons of Lunchbox Lockers Great grip on a budget is the lunchbox locker’s calling card. Price is the biggest pro for the lunchbox locker. They cost less than half the price of an air locker, and remember this is before factoring in the cost of a pneumatic operating system. The lunchbox locker is about a third of the price of a large-frame mechanical locker / automatic locker. Going with a lunchbox locker also pays off when it comes to installation. Since the process is less labor intensive than a large-frame locker installing a lunchbox locker costs less. The savings can be even more substantial if you handle the install yourself. The Spartan Locker's patent-pending design replaces the spider gears in a standard carrier case, does not use the thrust washers, and has a revolutionary spring-and-pin design that makes installation quick, easy, and much cheaper that other types of lockers! Further, in some cases, the install does not require the removal of the differential. A disadvantage of this is the lunchbox locker relies on the factory carrier for strength. Large-frame lockers, like the Grizzly and Zip, replace the carrier as a single unit and their case is constructed from a much stronger alloy steel compared to the factory carrier. Being locked all the time, mechanical lockers can cause accelerated tire wear. As with many modifications, it’s a game of trade-offs. Installation Tips and Tricks If you’re able to remove the spider gears with the carrier still in the housing the installation can be done without removing the carrier from the diff. If it’s too tight in there, the diff will have to be removed. Spartan Lockers come with a highly detailed installation manual that includes tons of photos and step-by-step instructions. The manual addresses installation in a variety of differentials. Basically, the Spartan Locker’s drivers are assembled with the alignment pins and springs installed. The installation wires keep the assembled unit together until installation is finalized then they’re removed releasing the spring tension that’s needed to operate the unit properly. Spartan Locker Installation Quick Tips For Use in Open Differentials Only Remember to Re-Install Carrier Shims and Bearing Caps in the Same Place Punch Mark Bearing Caps to Indicate Which Side to Install Them On Be Sure Tires are Same Circumference to Ensure Proper Locker Engagement Are Lunchbox Lockers for You? Vehicle usage is the tipping point. Not just how much your rig will see the street where the boisterous operation of the lunchbox locker comes into play but off-road usage as well. Your expectations on the trail; and how much you’ll be demanding from the driveline come into play. If you’re staying on the trail with moderate hill climbing, scrambling over rocks, and the like, the lunchbox is a good call. If you plan to be more aggressive and looking to get into some extreme situations where a great deal of torque and load shocking are the norm, a large-frame locker may be the way to go. When it comes to the ratcheting and clunking sounds the unit makes, read up on the subject. Some users report the sound isn’t that intrusive, others say the noise fades with use. As we indicated before, the performance game is made of trade-offs… but the payoff is big. Spartan Locker Highlights Big on Traction, Low on Cost For Use in Open Differentials Only Patent Pending Design Replaces Spider Gears Low-Cost Shop Installation - Can be DIY Installed Reliable 100% Lockup Power Transfer Features Heat-Treated 9310 Steel Internals for Enhanced Durability Shop Spartan Lockers or contact us at 866-631-0196

How To Use A Dial Indicator

The keys to properly using a dial indicator are precision and patience. The payoff is a long-lasting driveline. The dial indicator is one of those specialized tools that has an intimidating reputation, but as with many things, understanding the components of the tool and how they work is half the game. A dial indicator typically measures the backlash of a ring and pinion gear. It can also be used to measure runout, the untrue movement (wobble) of a rotating object like an axle, cam or crankshaft journal, wheel, brake rotor, or the input shaft of a manual transaxle/transmission. Precision is important because in ring and pinion jobs we are dealing with shims that can be paper sheet thin… as thin as three thousandths of an inch. The first step to dial indicator enlightenment is understanding the workings of the tool. Anatomy Of A Dial Indicator When measuring backlash in a ring gear the placement of the dial indicator is key. High-pinion and low-pinion applications have the drive side gear teeth on different sides of the ring gear. This will determine where the dial indicator is set up because measurements are made on the drive side of the tooth. The Setup A dial indicator is like a high-tech erector set. It can be extended and articulated in an array of angles. Setting up the unit starts with the magnetic base which is placed on the housing and then all the armature is configured to position the tip at a 90-degree angle on the drive gear tooth with the plunger in proper alignment with the gear’s rotation angle. A vast majority of dial indicators have magnets that you position to align the plunger and ring gear tooth. In whatever manner the base of your dial indicator secures to the housing, it must maintain a stable platform because every proceeding step relies on the accuracy and consistency of this starting point. Here, the diff housing makes a great anchor point but other applications may not offer so obvious mounting possibilities. The arm can be moved up or down the main shaft while also being adjusted inward and outward within the housing to more precisely line up the tip and the tooth face. This is where your erector set experience comes into play. There is an adjustment knob behind the dial that allows the dial assembly and plunger to swivel to better match the actuation of the tip with the angle of the gear tooth when the ring gear is moved. The goal is to make as much of a straight line measurement as you can. Tighten everything down to limit flex and be sure the tip is resting on the tooth face… any play or preload in this area will produce false readings. Also, be sure the plunger is not rubbing against the adjacent tooth which may also result in a faulty measurement. Shop Yukon dial indicators and measuring tools here. Measuring You can measure with the existing readout or zero-out the tool by loosening the bezel clamp and rotating the bezel. When measuring backlash on a ring gear be sure you’re only turning the gear and not the pinion which may influence the readout. Clamping or otherwise isolating the pinion is a good idea. When measuring a ring gear, the gear is rotated in both directions to produce freeplay. The amount of the movement is measured as straight-line travel by the tip and plunger. Even the runout of a ring gear can be evaluated by measuring the amount of movement the gear produces back and forth between the thrust bushings. Reading The Dial Most dial indicators have a one-inch stroke, meaning the plunger will only move one inch within the tool. The dial indicator’s range is denoted in the dial. The dial also has units of measure or accuracy indicated, typically in drivetrain operations a 1/1000 of an inch is the preferred unit. The main or outer dial is joined by the smaller revolution counter dial which indicates how many times the needle has gone around the outer dial. So, if the main needle travels around the outer dial twice the revolution dial will read 2. Or 0.200 inches. If the larger needle progresses past zero to 30 on the big dial, the total reading is 0.230 or 230 thousandths of an inch. Total Movement The amount of positive movement and negative movement indicated reveals the total movement. So, the measurement is made from the static beginning with the plunger engaged then it moves inward and outward and the number of units measured in each direction are added together. For instance, if the needle moves from plus five thousandths of an inch to minus 90 thousandths of an inch, the total needle movement is 15 thousandths of an inch. Additionally, if the needle moves 10 thousandths of an inch to the negative side and then five thousandths of an inch to the positive side the total movement is again 15 thousandths of an inch. Once you successfully set up the dial indicator measuring other gear sets will be super easy as long as they have the same pinion arrangement i.e. high pinion or low pinion, as the basic setup of the tool’s armature has been established and you’ll only need to fine tune the tip-to-tooth relationship. Dial indicators deserve a place of honor in your tool case. They expand our capacity, allowing us to do more jobs. They add quality to our work, by enhancing the accuracy of our actions. The end result is a job better done that will last for years to come, a win-win in anyone’s book. Shop Yukon Differential Tools