Copy of JL Metallurgy Overview

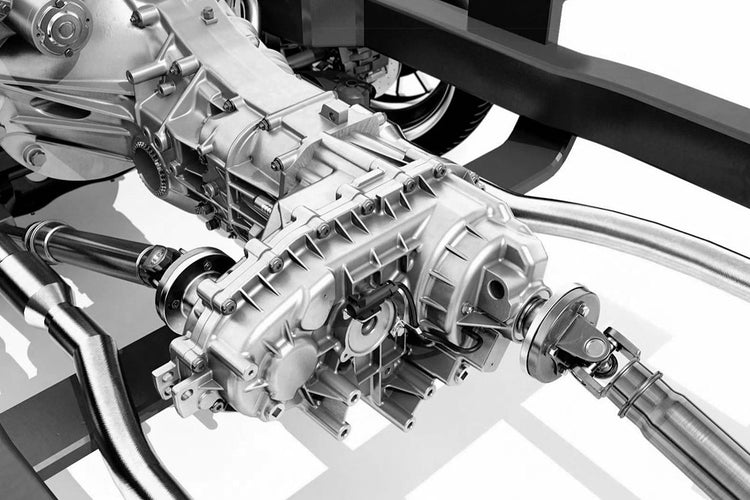

New Jeep JL platform provides design challenges in the automotive aftermarket The new JL platform from Jeep quickly became one of the significant introductions from carmakers in many years. Like every other Jeep platform, opportunities for aftermarket manufacturers to modify, lift, and design came quickly after the introduction. For aftermarket drivetrain engineers, working on the new Jeep JL platform provided with design challenges when it came to the ring and pinions. The JL launched with a new set of differentials including the D44JL Rear (M220), D44JL Front (M210) & D35JL (M200). Factory Engineers had designed the ring & pinions for higher efficiencies. Whether this had to do with increased mileage requirement or powertrain revisions, differential modifications were required throughout the platform. From a design perspective, this factory revision denotes a decrease in the hypoid offset from previous JK designs resulting in a smaller pinion head diameter with increased loading on the teeth. Stronger alloys, most notably an increase in the nickel content, are required to handle the increased loads. Most aftermarket manufacturers recognized the design change, that was the easy part. Only Yukon recognized that the design change required improvements to the metallurgyas well. Recognizing the significant changes in the OE gears for the JL platform, Yukon Engineers examined countless material and heat treatment options to effectively deal with the new hypoid offset. Yukon realized the need to manufacture the JL ring & pinion line with a premium higher strength 4320 material to hold up to the abuse and provide even higher strength than the JK. A year later, after testing Yukon against other aftermarket brands, it appears that Yukon was the only aftermarket company to move to the higher strength material and produce the strongest aftermarket gears associated with Jeep JL line.

Yukon Spring Rebate 2020

Online Form Mail in Form Item List Yukon Grizzly Locker – $50 Rebate Yukon Grizzly Locker – $50 Rebate Tear it up with our Grizzly Locker’s heat treated 8620 & 9310 Steel internals designed to dominate extreme torque and shock load Premium alloy steel and nodular iron cases are designed for performance quality strength with minimal deflection Large inner-clutch teeth are stronger than back-cut designs by 350%, allowing great resistance to shock load or broken axle failures Yukon Spin Free Kit – $175 Rebate Yukon Spin Free Kit – $175 Rebate Yukon’s top of the line Hub conversion kit uncouples your wheels from the front axle, letting it operate more efficiently, reducing drag for a smoother ride and boosting fuel economy Replace your inaccessible, worn and vulnerable factory unit bearings with our complete Yukon Spin Free kit that comes with our toughest outer axles forged from 4340 Chromoly Steel, and forged hubs on most applications. Clean and sleek, this kit includes Yukon Hardcore Locking Hubs that let you engage into 4WD to play hard and easily disengage for the road back home Yukon Driveshafts – $40 Rebate Yukon Driveshafts – $40 Rebate Provides the highest quality performance driveshafts Double cardan joints and high strength steel allow for increased articulation to accommodate lifts, reduced vibration, and improved durability on the trails 1310 – 1410 U-joints sizes available for high strength Available for JK, JL, and JT Jeep models Yukon Front Axle Kit – $100 Rebate Yukon Front Axle Kit – $100 Rebate Next-level strength and toughness from 100% 4340 Steel that undergoes Yukon’s stringent proprietary heat treatment process and in-house torque testing Tight tolerance yoke-end is the trick to a properly fitted u-joint that won’t vibrate or loosen Smooth and precise bearing journals are the secret to maximizing bearing and seal life, thanks to Yukon’s unique surface finishing treatment Yukon Zip Locker – $75 Rebate Yukon Zip Locker – $75 Rebate Yukon’s most impressive locker yet, forged from an entirely steel case to protect the internals with minimal deflection and maximum strength Air-operated intelligently designed locker, compact air compressor sold separately Bevel gears are optimized using our specialized design software to create a stress balanced tooth design that promotes superior strength and eliminates weak links Designed to handle extreme torque and shocks loads, heat treated 4320 & 9310 steel bevel gears and lock ring let you unleash power and stay locked until you disengage the locker Yukon Hardcore Locking Hubs – $40 Rebate Yukon Hardcore Locking Hubs – $40 Rebate Built for extreme off road, pulling, and performance featuring chromoly internals and steel construction for ultimate durability & strength Manual locking hubs provide the selectability between open axles for improved gas mileage, and reduced wear, and locked axles for maximum traction and grip when off-roading or towing Engagement comes from just a 1/3 turn of the all-steel, low-profile bezel to reduce impact with obstacles Proprietary coating on the locking gears for decreased friction & long life

Identifying Borg Warner Transfer Cases

Getting a cross pin shaft to clear a thick gear

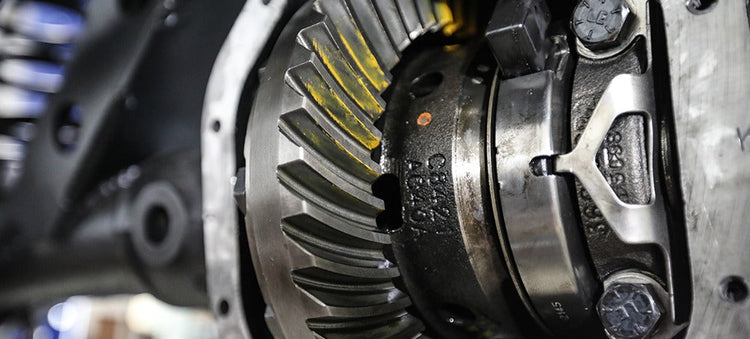

In many cases it is necessary to grind one or more teeth on a ring gear in order to reinstall the cross pin in many c-clip style rearends. In most cases this will not interfere with the contact pattern of the gear or decrease the strength in any way as long as it is done properly. In some rare instances you may need to grind as much as ¼ of one or two teeth away. Although we have seen vehicles run with half of a ring gear or pinion tooth missing, we do NOT recommend pushing your luck that far. However, we have no problem running a gear-set in our own vehicles with 1/4 of tooth ground off of the toe or 1/8th of the heel of one or two of the ring gear teeth. Gear grinding should always be done on the bench top, not while gear is installed. This is to avoid getting metal and other contaminants into the housing or differential carrier. In most cases you will only need to grind about 1/8” off the corner of the tooth. After the desired amount of material is removed, you need to use a medium grit 3M disk to round the edges and remove any burrs. Be sure to clean a gear thoroughly before you reinstall it into the housing. Getting a cross pin shaft to clear a thick gear - In many cases it is necessary to grind one or more teeth on a ring gear in order to reinstall the cross pin in many c-clip style rearends. In most cases this will not interfere with the contact pattern of the gear or decrease the strength in any way as long as it is done properly. In some rare instances you may need to grind as much as ¼ of one or two teeth away. Although we have seen vehicles run with half of a ring gear or pinion tooth missing, we do NOT recommend pushing your luck that far. However, we have no problem running a gear-set in our own vehicles with 1 4 of tooth ground off of the toe or 1 8th of the heel of one or two of the ring gear teeth. Gear grinding should always be done on the bench top, not while gear is installed. This is to avoid getting metal and other contaminants into the housing or differential carrier. In most cases you will only need to grind about 1 8” off the corner of the tooth. After the desired amount of material is removed, you need to use a medium grit 3M disk to round the edges and remove any burrs. Be sure to clean a gear thoroughly before you reinstall it into the housing.

Properly setting preload with side adjusters

There are several types of rear ends that use a threaded side adjuster be it a single adjuster or one on both sides of carrier. The most commonly known rears with this type of carrier adjustment are the Chrysler 7.25-8.25-8.75-9.25, Ford 9”, GM 8.25” IFS, Suzuki Samurai, & Toyota. The GM 9.5” is a little different than most as one side uses shims but the other side is the threaded adjuster. Randy’s has tools that work with a 1/2” drive ratchet or breaker bar that work much better than beating the heck out of the adjuster with a punch & hammer. These side adjuster tools are priced starting at $29.00. Most people are reluctant to really crank on these adjusters to preload the carrier bearings. It is perfectly normal to have 150-200 ft lbs of torque on the side adjusters. It is very important to obtain good preload to avoid damage to your differential. At Randy’s, our service shop uses a 1/2” breaker bar, as shown in illustration 1A. The reason we do this is because as you accelerate, the pinion wants to make the ring gear deflect. The more power, the more it will tend deflect. Housings always flex, some more than others, depending on whether it’s stock or an aftermarket nodular. If you put a lot of preload on the carrier bearings it also preloads the housing. Since the housing is already flexed, it is not likely to flex even more causing the ring gear to move away from the pinion resulting in broken teeth. Properly setting preload with side adjusters - There are several types of rear ends that use a threaded side adjuster be it a single adjuster or one on both sides of carrier. The most commonly known rears with this type of carrier adjustment are the Chrysler 7.25-8.25-8.75-9.25, Ford 9”, GM 8.25” IFS, Suzuki Samurai, & Toyota. The GM 9.5” is a little different than most as one side uses shims but the other side is the threaded adjuster. Randy’s has tools that work with a 1 2” drive ratchet or breaker bar that work much better than beating the heck out of the adjuster with a punch & hammer. These side adjuster tools are priced starting at $29.00. Most people are reluctant to really crank on these adjusters to preload the carrier bearings. It is perfectly normal to have 150-200 ft lbs of torque on the side adjusters. It is very important to obtain good preload to avoid damage to your differential. At Randy’s, our service shop uses a 1 2” breaker bar, as shown in illustration 1A. The reason we do this is because as you accelerate, the pinion wants to make the ring gear deflect. The more power, the more it will tend deflect. Housings always flex, some more than others, depending on whether it’s stock or an aftermarket nodular. If you put a lot of preload on the carrier bearings it also preloads the housing. Since the housing is already flexed, it is not likely to flex even more causing the ring gear to move away from the pinion resulting in broken teeth.