Worms Can Help Off-Road Traction

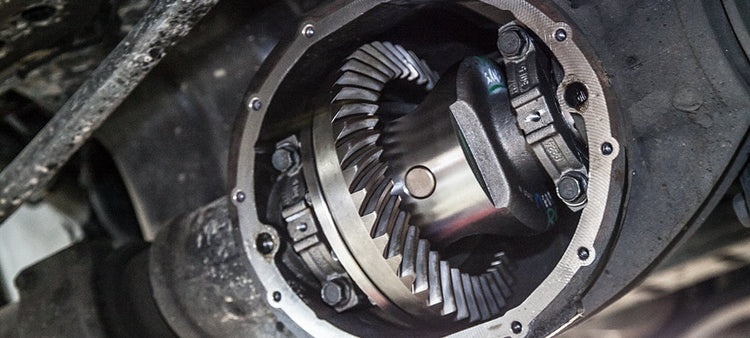

Even though the Gleason Torsen limited slip differential has been out of production for about thirteen years now, I still get quite a few questions about it. The Gleason Torsen was a gear driven, torque-sensing limited slip differential that was very smooth and reliable, as long as it was not used with tall tires. Although Gleason decided it was too difficult to make a strong yet economical unit, Tractech (maker of the Detroit Locker and EZ Locker) has been able to develop their own line of torque-sensing limited slips they call the Detroit TrueTrac. Detroit TrueTracs are similar in design to the Gleason Torsen , only the TrueTracs hold up well with reasonably tall tires. They use worm wheel gears that work on the same principle as a worm gear. When the unit is loaded, the worm wheels are forced away from each other and against the case. They develop locking torque by the light friction between the worm wheels and the case. This light friction is multiplied by the ratio of the worm wheel, which depends on the size of the worm wheel relative to the size of the side gear. The amount of torque biasing or lockup can be changed by the manufacturer by simply changing the diameter of the gears, or the pitch and spiral of the teeth. A larger difference in the size for the worm wheels and side gears (smaller worm wheels and larger side gears) will increase the lockup force. Increasing the pitch and spiral of the teeth will also increase the lockup forces. Like everything, there is a limit as to how much lockup force is reasonable. Making the unit too “aggressive” will cause tire scrub during everyday driving and will cause the unit to wear out too quickly. All of the feedback that I have received from customers indicates that the unit works very well for mud and snow, while going unnoticed during every day driving. When used in situations like rocky trails where one wheel gets off the ground, the unit will not lock up 100%. Light application of the brakes will help the differential engage more transferring power to the tire that is still on the ground. For extreme situations where the vehicle will have one wheel in the air often a locking differential provides better power transfer to the wheel on the ground. Detroit TrueTracs are designed for medium duty 2WD and 4WD applications. They work well in the front and rear, and are so smooth that there is no hint of resistance in the steering wheel when used in front drive steering axles. Like the Gleason Torsen , the Detroit TrueTrack does not bang and clunk, has no clutch chatter, does not wear out like clutch type positractions, does not need limited slip additive, and needs no preload or clearance adjustments. Sounds too good to be true? The only drawbacks to the TrueTracs are limited applications and their inability to lockup 100% like a locking differential can. Although Gleason no longer makes the Torsen differential, the Detroit TrueTrac is a proven design that is available for many popular applications.

What Does “Complete” Really Mean?

Have you ever had to call around town on a Friday to find pinion shims or a crush sleeve so you could be on the trail for the weekend? Working on a rear end is hard enough with the right parts, and can be downright impossible with the wrong parts. A good installation kit can make the job a lot easier and save hours of frustration. Every distributor claims to have the best installation kits available. I have seen a number of items labeled “Installation Kit” or “Master Kit” that didn’t deserve to be named as such. Since there is really no established standard, the terms will always be used loosely and it is up to the customer to put the sales person through the drill of explaining what is in each kit, in detail. There are many good questions to ask when ordering. Does the kit include good instructions? Does it include ALL of parts necessary to rebuild or setup the rear end completely? Are both pinion and carrier bearings included in the kit, and are they the highest quality available? Many kits use cheap import bearings and seals. If the salesperson is not certain what kind of parts their kit uses, ask them to open the box and see. Many kits do not include useful carrier and pinion shims. This is due to the cost of making good shims. Are there just enough shims for one adjustment, or does the kit contain enough shims to setup the rear end from scratch? In my opinion, a complete “Installation Kit” includes: both pinion and carrier bearings, a crush sleeve or preload shims, enough pinion depth shims to set the depth without having to reuse any of the original shims. For most applications, a complete set of carrier shims. A high quality pinion seal, an OEM quality pinion nut, a gasket or silicone for the cover, Loctite® or thread locker for the ring gear bolts and pinion nut, an instruction manual with pattern diagrams and details that really help, and real gear marking compound. (If you are looking for gear marking compound in a handy tube, try GM part number 1052351.) It really doesn’t matter which parts a supplier includes in their installation kit, as long as they explain, in detail, what the kit contains. There are many high quality kits out there. Ask a lot of questions and don’t take “I’m not sure” for an answer. Remember, this is your rear end we are talking about.

Do I Really Need To Buy Another Carrier?

When changing the gear ratio for more power or more speed, sometimes a new ratio requires a different height carrier case. Carrier height changes are commonly referred to as a “carrier break”, although this doesn’t have anything to do with broken parts. What it does refer to is the difference in the ring gear mounting height on the carrier case itself or a breaking point from one height to another. When the gear ratio is changed, it is accomplished by changing the number of the ring gear teeth and / or the pinion gear teeth. The gear ratio is determined by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. For example, 41 divided by 10, which equals 4.10 for a gear set with 41 ring gear teeth and 10 pinion teeth. As the ratio increases numerically, the ring gear usually stays the same diameter which requires that the pinion gear diameter gets smaller. The smaller pinion gear will not reach the ring gear unless the ring gear is made thicker or the carrier case mounting flange is moved closer to the smaller pinion gear. The ring gear material is very expensive and it is far cheaper (especially when building millions of rear ends for production) to change the position of the carrier flange. Changing the flange height usually requires very little or no extra material on the carrier case. An example of a popular rear end that has a carrier break is the Dana Spicer model 44. The D44 uses two different height carriers. When using ratios that are 3.73 or numerically lower (such as 3.54 or 3.07) a short carrier case is used to allow the large pinion gear to fit in the housing and move the carrier flange far enough away for the ring gear to have thickness left to support teeth. When using ratios that are 3.92 or numerically higher (4.09 all the way to 5.89), a taller carrier case is used to move the ring gear closer to the small pinion, without having to use an excess of expensive ring gear material. In order to avoid the expense of a new carrier case, some people use ring gear spacers. A spacer is a quick fix, but from my experience, not a good idea. If the spacer pushes the ring gear up off of the pilot surface that centers it on the carrier, it will have to rely on the ring gear bolts to hold it centered. The ring gear bolts are neither strong enough or accurate enough to center the ring gear correctly. This in turn causes the ring gear to “walk” around on the carrier and the tooth contact will suffer. Before you know it, the gear set will be noisy, wear out, orbreak. I have seen a very few cases where the ring gear pilot surface on the carrier is large enough that it could still touch the ring gear when using a spacer. This is somewhat better than no contact, but the bolts will still be overloaded and the unit will not last. If your ratio change calls for a different height carrier case,there are a few options that will work just fine. Thick ring gear ring & pinion sets are available for many popular applications. The thicker gears have absolutely no side effects. The thicker ring gear has lots of material exposed to the oil so it runs just as cool as a thin gear set. Not only has the aftermarket used thick ring gear sets for many years, many original equipment vehicles have used thick ring gear sets or offered thick gear set options. For example, Ford does not use any carrier breaks on any of their corporate rear ends which means that many of their gear sets could be considered “thick”. The other option that will solve the problem of dealing with a carrier break is the obvious. Buy a new carrier. This may sound expensive and in some cases it is. In many cases the carrier case is less than $100. Or, it may be a good time to upgrade to a positraction or locker. Replacing the carrier with a posi or locker allows you to upgrade and get the appropriate carrier at the same time. Next month will include a list of carrier brakes for popular truck, passenger car, and Jeep rear ends.

Differential Cost: When Is Too Much Really Too Much?

We get a lot of questions asking how much it should cost to have a rearend setup. Unfortunately, the answer is never simple, due to all the variables involved. The hourly rate a shop charges can vary from as little as $60 to over $200 per hour. Labor charges may depend on location, competence, warranty, overhead, and the individual shop or mechanic’s desire to work on differentials. Access to a flat rate book that provides standard hours required to do the job can be helpful. Ultimately, the shop is going to charge whatever they feel is fair, and we have found the flat rate books to be misleading at times. The guidelines we are about to present are only provided to help the reader in their search for a fair deal and should not be taken as gospel. If someone wants to charge more, and you want to have them do the work, then the only solution is to pay the price. However, if you feel that an equally good job can be done elsewhere, then so be it. Always consider the cost to be secondary to the quality of the work you receive. The following rates are per axle for most passenger cars, Jeeps, mini trucks, and half ton trucks, if the vehicle is driven to the shop: Rebuild with new bearings and seals using same ring & pinion: 4 to 6 hrs. Install ring & pinion, and bearings and seals if needed: 5 to 7 hrs. Install limited slip or locker, without removing pinion: 3 to 4 hrs. This list of variations or exceptions to the above rule are a few of the common things that make the job more difficult, or easier, and require an adjustment to the cost: Differential is brought in out of the vehicle: Subtract 1.5 hrs. Three quarter and one ton trucks: Add 1 hrs. General Motors independent front suspension: Add 3 to 4 hrs. Late model independent front suspension (excl GM): Add 1 to 4 hrs. Two-piece tapered axles: Add 1.5 hrs. Motorhomes or large Box Vans that do not fit on common lift: Add 4 to 8 hrs. Another thing to be aware of when shopping around is warranty. Any shop that is familiar with differentials will probably have some limitations to their warranty. Some of the common warranty restrictions that we use in our shop are: mini and mid-size trucks (Jeeps, Ford Rangers with 7.5″ diff, Toyota trucks) with tires taller than 31″; half ton trucks with tires taller than 33″; three quarter and one ton trucks with tires taller than 35″; trucks used for towing have a shorter than standard warranty; and vehicles used for competition or racing are not warranted. These may seem like extreme limitations, but they are sometimes necessary to protect the shop from people who abuse their vehicles on or off road. If you purchase parts directly from the shop doing the work, expect to pay a little more. Every shop has the right to make a profit when stocking or handling parts. And shops can be very helpful if there’s ever any warranty issues related to the parts. Use your best judgment and remember that supply and demand always hold true when it comes to quality parts and service. Popular Resources: New Gear Break-In Properly Setting Preload with Side Adjusters Size Matters

Myths Regarding Differentials

Over the years I have heard a lot of myths regarding the setup and design of differentials. Anyone with a little experience can fix a diff. I have heard time and time again that the following situations make a person a qualified differential expert: They are an old-timer, a grizzled guy with stained overalls. They are a machinist. They are in a four-wheel drive club. They have built a few rear ends for their buddies. I believe there are only a few people who really know how to setup a rearend correctly, and they have learned from years of experience and collecting facts. The gear ratio in the front of a four wheel drive has to be different from the rear so the front wheels will pull more. There have been many different ratio combinations used in four-wheel drive vehicles, but not so that the front will pull more. Gear manufactures use different ratios for many different reasons. Some of those reasons are: strength, gear life, noise (or lack of it), geometric constraints, or simply because of the tooling they have available. I have seen Ford use a 3.50 ratio in the rear with a 3.54 in the front, or a 4.11 in the rear with a 4.09 in the front. As long as the front and rear ratios are within 1%, the vehicle works just fine on the road, and can even be as different as 2% for off-road use with no side effects. 1 point difference in ratio is equal to 1%. To find the percentage difference in ratios it is necessary to divide, not subtract. In order to find the difference, divide one ratio by the other and look at the numbers to the right of the decimal point to see how far they vary from 1.00. For example: 3.54 ÷ 3.50 = 1.01, or 1%, not 4% different. And likewise 4.11 ÷ 4.09 = 1.005, or only a 1/2% difference. These differences are about the same as a 1/3″ variation in front to rear tire height, which probably happens more often than we realize. A difference in the ratio will damage the transfer case. Any extreme difference in front and rear ratios or front and rear tire height will put undue force on the drive train. However, any difference will put strain on all parts of the drivetrain. The forces generated from the difference have to travel through the axle assemblies and the driveshafts to get to the transfer case. These excessive forces can just as easily break a front u-joint or rear spider gear as well as parts in the transfer case. Positraction is better than limited slip. I have heard many people call a standard open differential a “limited slip” and I have been asked for a limited slip instead of a positraction because they wanted something that was not too aggressive. From my experience positraction and limited slip are just two different names for the same thing. If anyone can find a SAE standard or printed definition please let me know and I will gladly correct myself. Popular Resources: Diagnosing Noise (Part 1) Ford 9 Inch Differential Information Four Critical Ring & Pinion Settings