Introducing ICON Vehicle Dynamics Shock Absorbers

RANDYS is excited to be selling ICON Vehicle Dynamics products. We will be offering ICON suspension systems, steering components, body armor, and signature wheels. Understanding ICON’s line of shocks will help you make the right decision on upgrading your ride’s suspension be it via shocks only or by employing a complete suspension lift system. ICON shock absorbers are available in three different variations. The VS 2.0 Aluminum Series, which can be ordered with external reservoirs, the VS 2.5, which is larger and a strictly remote reservoir affair, and the line-topping VS 2.5 Omega, which brings some motorsport tech to the party. The ‘VS’ in ICON shock model names stands for Vehicle Specific, a call out to how all ICON shocks are valved to optimize performance in their intended application. All shocks are rebuildable, can be re-valved, and are filled with premium 5WT shock oil. ICON VS 2.0 Aluminum Series Shocks Targeting daily driver/weekend warrior rigs, the 2.0 Series is a balanced blend of on-road smoothness and off-road toughness. All ICON shocks are designed and built on a per application basis to be superior to stock. The 2.0 is a nitrogen-charged monotube design with a 5/8-inch diameter chrome plated hardened steel shaft that resists corrosion and pitting. The 2.0 features an anodized 6063 aluminum body and 6061 aluminum rod end, top cap, and internals to ensure strength and durability over rugged terrain. They can be ordered with an external/remote reservoir that’s connected via a hose for mounting on the frame rail or, as pictured, in a piggyback setup. Other attributes include polyurethane bushings, zinc-plated sleeves, and forged-steel mounting stems for OE factory-type fitment. Shop ICON 2.0 VS Series Shocks ICON VS 2.5 Aluminum Series Shocks The 2.5s are a definite step up from the 2.0 Series They feature remote reservoirs for improved heat dissipation, a larger one-piece impact extruded 6061 aluminum shock body that measures 2.5 inches in diameter, and a larger piston rod. The larger diameter shock body translates into better performance because the piston has more surface area which delivers more damping force. The shock’s stout piston rod measures 7/8 inches in diameter and is better able to handle prolonged engagement and side loading. ICON’s innovative internal “Bump Zone” provides more control as the shock approaches full compression, increasing damping force by 20% to combat suspension bottoming during high-velocity suspension movements. The Bump Zone is created by an internal billet 6061 aluminum manifold positioned a few inches below the top cap of the shock. The 2.5’s external reservoirs can be configured as a piggyback (attached to shock body) or remote (connect via a hose for mounting on frame rail). The 2.5 has sub-variants that enhance performance with adjustable damping features. Shop ICON 2.5 VS Series Shocks Variant: ICON VS 2.5 Aluminum Series With CDCV This version has all the features of the 2.5 but adds ICON’s Compression Damping Control Valve (CDCV) to the mix. This feature adds 10 points of compression adjustability to fine tune performance and better match driving conditions. Each CDCV-equipped piston is custom built per application with different valve stacks. Adjustments are made from S to H and the unit is calibrated so the #4 setting represents the stock or default damping force where the shock behaves as the factory intended. This allows the user to dial in a firmer or softer ride that really adds to the versatility of off-road vehicles, especially weekend warriors that pull double duty as a commuter during the work week. Shop ICON 2.5 VS Series Shocks With CDCV Variant: ICON VS 2.5 Aluminum Series With CDEV ICON adds electronic control to the damping adjustment equation with its VS 2.5 Aluminum Series CDEV shock. This technological juggernaut meters the flow of oil to regulate and adjust compression damping on-the-fly with sample times of less than 40 milliseconds. The system can make extremely precise adjustments for varying terrain, as you drive, and it’s all tuned to your individual vehicle application. Powered by ICON Intelligent Control (IIC) and a proprietary ICON mobile app, the system uses information from an onboard g-force sensor and gyroscope to perform calculations based on algorithms and user-defined settings to predict terrain and adjust shock settings as needed. Shop ICON 2.5 VS Series Shocks With CDEV ICON VS 2.5 Series Omega Shocks So advanced it’s its own shock, ICON Omega Series shocks are based on the standard 2.5 unit but use technology usually reserved for competition shocks like Trophy trucks and other extreme off-road vehicles. These shocks feature an external bypass tube that routes a metered amount of shock oil around the piston. Like a shock within a shock, the tube has its own valving and 28 detented settings of compression and rebound adjustment. This allows the piston to encounter less force in the bypass zone for moderate situations and additional force, near the end of its stroke, outside of the bypass bump zone, during more spirited off-roading. Shop ICON 2.5 VS Omega Shocks ICON Suspension Systems All the shocks featured here are the foundation for ICON’s complete suspension systems that provide mild to aggressive lifts, auto-leveling, and extreme off-road performance. Offered in a multitude of stages, ICON suspension systems can include tubular or billet upper control arms, tubular or billet trailing ams, a number of different spring rates, and a wide choice of lifts. Shop ICON Suspension Systems

Strengths & Advantages Of The Spartan Helical LSD

When you’re driving in a normal manner a positraction limited slip differential is pre-loaded and provides equal traction to both wheels. Mashing the throttle, taking a tight corner aggressively, or working through loose gravel trails will result in the limited slip differential applying more torque where it’s needed. This enhances the grip, control, and predictability of the vehicle. Understanding Clutch- & Gear-Type Limited Slip Differentials The main difference between LSD types is how each applies additional torque when the unit is properly loaded. A clutch-type unit uses an array of springs to apply pressure to the side gears which puts pressure on the clutch packs in the outer part of the carrier. When a tire starts slipping, the clutch packs are engaged with differing resistance. The clutches compensate to maximize traction between the tires, transferring more torque to the tire that has the best grip while reducing torque transfer to the tire that has less grip. A gear-type Spartan Helical LSD from USA Standard Gear has no frictional surfaces to initiate torque transfer. It uses floating helical-cut worm gears that operate in pockets and mesh together. When acceleration or wheel slippage occurs, axial and radial thrust is applied to the helical gear pinions in their pockets. Under these loads, the gears lock and more torque is transferred to the tire with the best traction in a mild progressive manner as torque is withheld from the tire that is slipping. Advantages Of Gear-Type Spartan Helical Limited Slip Differential The Spartan Helical LSD limited slip differential provides smooth engagement, quiet operation, and requires no maintenance because there are no clutches to rebuild. The unit’s 10-pinion design has a strength advantage over an equivalently sized 6-pinion or 8-pinion gear-type unit because it has more points of contact and a greater surface contact area to deliver optimal load distribution. This LSD is built tough. The Spartan Helical LSD is a fully assembled unit featuring a forged 8620 grade steel case and stout 8620 alloy internals for superior durability. Fits Dana 30 front differentials 27 spline, 3.73-and-up ratio Forged 8620 grade steel case, 8620 alloy internals for superior durability No clutches, no need to rebuild Shop Spartan Helical LSD Other Gear-Type Diffs Available From RANDYS The Spartan is not the only gear-type diff offered by RANDYS. We also have helical gear limited slip differentials for select GM and Chrysler applications. GM & Chrysler 11.5-Inch Helical Limited Slip Differential This 30-spline unit fits Chevrolet, GMC, Dodge, and Ram 2500- and 3500-series pickups produced from 2001 to 2019. GM 8.5- & 8.6-Inch Helical Limited Slip Differential This unit fits a multitude of half ton 1500-series pickups and late model cars and SUVs from The General. It’s a 30-spline unit that works in diffs with ratios of 2.73 and up. Chrysler/AAM 11.8-Inch Helical Limited Slip Differential This unit is designed to fit model year 2016-and-up Ram 3500 pickups with a 16-bolt ring gear. Chrysler 10.5-Inch Helical Limited Slip Differential This 30-spline unit fits 2003 to 2010 RAM 2500 pickups and 2011 to 2013 RAM 1500 pickups.

Nic Ashby Wins 2020 American SuperJeep Challenge Builder of the Year

Nic Ashby Wins 2020 American SuperJeep Challenge Builder of the Year – Proves Mettle at King of the Hammers with Yukon Gear & Axle® Drivetrain Components GRDLOC, A 1987 CJ7 MODIFIED JEEP® WRANGLER BUILT BY ROCKSTAR PERFORMANCE GARAGE OWNER NIC ASHBY FEATURES YUKON GEARS, AXLES AND DRIVESHAFTS Everett, WA (February 17, 2020) – Yukon Gear & Axle®, the leading performance off-road drivetrain supplier in North America, congratulates Rockstar Performance Garage owner Nic Ashby for being named 2020 SuperJeep Challenge Builder of the Year. Ashby’s win at MotorTrend’s 2020 American SuperJeep Invitational Championship was supported by Yukon Gear & Axle gears, axles and driveshafts, a Grizzly Locker locking rear differential and a Yukon Zip Locker in the front. The inaugural event was held last month at the conclusion of King of the Hammers off-road race in Johnson Valley, California. GRDLOC, Ashby’s modified 1983 CJ7 Jeep Wrangler entry, won unanimously by proving its mettle at handling desert and rock climbing as judged by an elite and diversified panel of industry experts – Courtney Hansen, Terry Madden and Greg Henderson. The project, three years in development, was also supported by many top notch aftermarket brand sponsors giving the on and off road vehicle its unique capabilities and style. GRDLOC featured a 4.4 supercharged Cadillac Northstar forged V8, Trophy Truck sized 3.0 King Shock Coilovers, Bullet Liner coated olive drab paint job, Scosche 12v Power Sport/Lifestyle Mounts, Throttle Down customs Race Frame, PRP Racing Seats, Mickey Thompson 46” tires, Genright Offroad Aluminum Armor, Billet KN Filters intake, Forged wheels, 8 piston brakes from R1 Concepts, 9 speaker Kicker audio sound system, Rugged Radios bluetooth internal comms, 7 independent coolers from Mishimoto and a 87 Dodge KingPin Front axle/2001 11.5” AAM rear axle from Yukon Gear and Axle. The judges and Tony May, Executive Producer of the American SuperJeep Challenge, was quick to point out that Ashby’s GRDLOC stood out from the field for its marriage of form, function and creativity to unequivocally earn the title. Ashby shared that this build has been his passion as well as for everyone on his team at Rockstar Performance Garage and LDRSHIPdesigns. Rockstar Performance Garage is a collaboration between Rockstar Energy Drink and LDRSHIPdesigns to build first Lifestyle Garage. “I am very thankful to MotorTrend for developing this exciting invitational event to help showcase what can be accomplished with the Jeep Wrangler, and to Yukon Gear & Axle for their incredible technical support, and all of my sponsors who have been there believing in this project from start to finish,” he added. Neal Hollingsworth, RANDYS Worldwide Director of Marketing says, “Nic is a visionary that is fearless in his approach to life and builds. We are very proud of his accomplishment as an entrepreneur and look forward to supporting him with more projects, which we suspect will be equally as interesting, award winning and fun. It was a privilege to be a part of the development of this incredible project with so many industry leading brands and to support him at events throughout the year.” For more information about Yukon Gear & Axle call toll free at 888.905.5044, email info@YukonGear.com or visit www.YukonGear.com, or connect with Yukon Gear & Axle on Facebook, Instagram and YouTube to keep up with the latest product introductions, builds and events.For more information about Rockstar Performance Garage, email media@ldrshipdesigns.com, or call 631.334.3864, or visit www.rockstarperformancegarage.com. About Randys Worldwide Established in 1982 and based in Everett, Washington, RANDYS Worldwide® is the leading distributor of aftermarket drivetrain and performance parts for the general automotive, motorsports, and off-road enthusiast. With a variety of products for cars, SUVs, and light duty trucks, RANDYS’ core business is focused on the distribution and manufacturing of parts through four major company brands: RANDYS Worldwide, Yukon Gear & Axle®, USA Standard Gear® and Zumbrota Drivetrain. RANDYS also has the industry’s only fully integrated differential search finder, Diff Wizard® that provides consumers with direct search results on their specific drivetrain needs. To learn more about RANDYS Worldwide, visit www.randysworldwide.com. About American SuperJeep Challenge Each year, Super Jeep Officials will tour pre-determined Jeep & Off-Road Events from coast-to-coast holding SuperJeep Qualifiers. Winners will be invited to attend & compete in The SuperJeep Invitational Championship held every January. Only one builder will be named America’s SuperJeep Builder of The Year. The year’s previous winner (GRDLOC) will have to dethrone as Champion by a better more capable build. About Rockstar Performance Garage Rockstar Performance Garage is collaboration between Rockstar Energy Drink and LDRSHIPdesigns to build the first Lifestyle Garage. RPG is known for unique vehicle builds that push the limits of form and function. The team at RPG also includes a best-in-class media team, providing expert videography and photography services that capture every aspect of the build, both in the garage and in action on the trail or track. If you can think it, we can do it at Rockstar Performance Garage. For more information visit: https://www.rockstarperformancegarage.com.

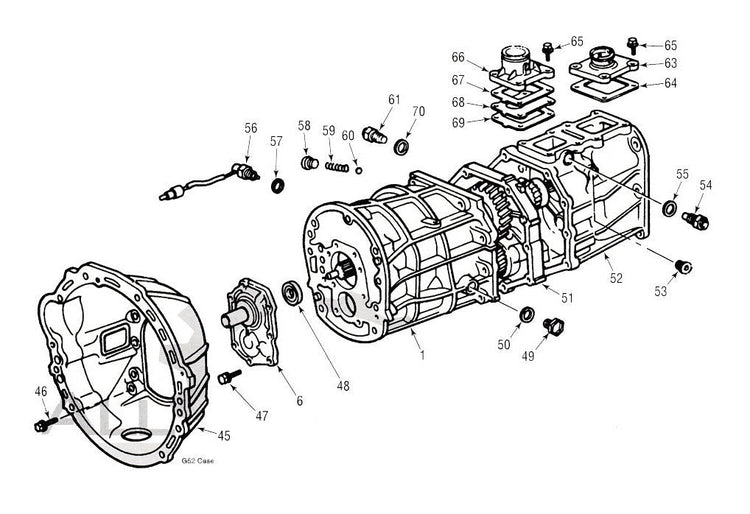

Jeep Wrangler Guía de observación de la transmisión

AX-15 – Manual de 5 velocidades Jeep Wrangler: 1988.5 - 1999 con 6 cilindros en línea, 4.0 litros Hechos: Se reemplazó una caja de cambios débil Peugeot BA10 Relacionado con la Toyota Supra Turbo R154 manual La mejor transmisión de 5 velocidades instalada en un Wrangler Consejos: Carcasa intermedia completamente de aluminio Solo se instala en un motor de seis cilindros. Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 16 1/2” Estrías Saliente: 7 1/8” Relaciones de transmisión: 1 1ª primera 3.83, 2ª segunda 2.33, 3ª tercera 1.44, 4ª cuarta 1.00, 5ª Quinta 0.79 AX-5 – Manual de 5 velocidades Jeep Wrangler: 1984 - 2006 XJ, YJ, TJ con 4 cilindros en línea de 2.5 litros Hechos: Quinta marcha propensa a fallas, sincronizadores deficientes, fugas en los rodamientos (anteriores a '94) Las variantes AX-5 incluyen Toyota G52, W58 y R151 Consejos: Carcasa intermedia completamente de aluminio, placa intermedia de hierro fundido Parece AX-15, así que ten cuidado. Solo se instala en un motor de cuatro cilindros. Eje de entrada de 14 estrías Eje de salida de 21 estrías Largo: 15 5/8” Estría Saliente: 7 1/2” Relaciones de transmisión: 1ª primera 3.92, 2ª segunda 2.33, 3ª tercera 1.44, 4ª cuarta 1.00, 5ª Quinta 0.85 NV3550: manual de 5 velocidades Jeep Wrangler: Wrangler 2000 - 2004 con 6 cilindros en línea de 4.0 litros Hechos: AX-15 reemplazado Compatible con la versión de 23 estrías de la caja de transferencia NP231 Consejos Carcasa de aluminio Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 16 3/4” Relaciones de transmisión: 1ª primera 4.01, 2ª segunda 2.32, 3ª tercera 1.40, 4ª cuarta 1.00, 5ª quinta 0.78 NSG370 – Manual de 6 velocidades Jeep Wrangler: Wrangler de 2005 en adelante, Wrangler Rubicon de 2004 en adelante Hechos: NV3550 reemplazado Compatible con 4.0 litros I6 y 3.8 litros V6 Consejos: Caja completamente de aluminio Eje de entrada de 10 estrías Eje de salida de 23 estrías Largo: 23 1/2” con 6 campanas de acoplamiento en línea Largo: 24 3/4” con campana de acoplamiento V6 de 3.7 L Relaciones de transmisión: 1ª primera 4.46, 2ª segunda 2.61. 3ª tercera 1.72, 4ª cuarta 1.25, 5ª quinta 1.00, 6ª sexta 0.84

Ian "Big Tire" Johnson Spin Free Installation Video

Yukon Spin Free Kits Freewheeling in the Name of Fun and Efficiency Ian Johnson, the host of the TV show “Four Wheeler” on the MotorTrend Network, runs through all the details involved in installing a Spin Free Kit in the accompanying video. The four-wheel-drive systems on some Dodge and Jeep applications are engineered to turn the front axles and transfer case gears when the vehicles are in two-wheel drive mode. This is wasteful on two fronts. First is the wear and tear factor… which is complicated by the fact that these systems feature non-serviceable, failure-prone bearing assemblies. Then there’s the negative impact all the energy used turning the front drivetrain has on fuel economy. Yukon Spin Free Kits swoop in like a superhero to save the day by allowing the front drivetrain to freewheel. These kits replace the failure susceptible and expensive factory unit bearings with serviceable tapered bearings and races. The result is not only a design which is easier and more economical to maintain, but one that offers significant increases in fuel efficiency because mpg-stealing parasitic drag in the front drivetrain is reduced. Each Spin Free Kit includes new wheel hubs, spindles, high-strength Yukon 4340 chromoly outer axles, Yukon Hardcore premium locking hubs, high-quality bearings and seals, and all the hardware needed for installation. Kits are accompanied by a limited lifetime warranty against manufacturing defects for as long as you own the vehicle. Wasted effort is frustrating. Unnecessary wear and tear and costly repairs are frustrating. Sacrificing fuel efficiency is frustrating. Yukon Gear & Axle Spin Free Kits relieves the frustration and makes your rig less expensive to maintain while allowing it to run longer between fill-ups. It’s a win-win. About Ian Johnson With his big hair and big fabrications skills, Ian is a well-known personality in the off-road industry. A former high school auto shop teacher, Ian first hit the big time in 2005 as part of Spike TV’s Powerblock weekend programming. Ian co-hosted the popular “Extreme 4x4,” a hardcore how-to show that highlighted the building and modifying of off-road vehicles. After the Powerblock was cancelled in 2013, the show transitioned to “Xtreme Off Road” (XRO) on Paramount’s Power Nation programming block. Ian left XRO in 2017. He appeared briefly on “Big Tire Garage” before manning the helm of the highly successful “Four Wheeler” show when it debuted in 2019. Like his TV segments, this installation video goes full-tech as Ian highlights all the critical steps with enthusiasm and depth as only he can do. Check it out.